David Holt

When you pay a technician for eight hours, but you can only charge four hours to the customer, that’s a losing proposition for the company. To improve business profits, you should do everything you can to reduce unapplied labor.

According to a study conducted by Carrier Corporation, ‘unapplied labor’ is one of the biggest profit-killers in the HVAC industry. In fact, this is true in every labor-intensive service industry that hires technicians to repair or replace all types of equipment.

When properly implemented, National Comfort Institute’s (NCI) Air Upgrade process helps you attack this common profit-destroyer. While that’s reason enough to adopt this innovative process, here are 10 HVAC system truths made better by Air Upgrades that will motivate you and your team to take immediate action:

10 HVAC System Truths to Motivate Air Upgrade Implementation

- You can’t properly charge a refrigerant system without the required airflow moving across the evaporator coil.

- Low superheat and high head pressure readings are common with improper fan airflow.

- Compressor failure due to refrigerant flood-back happens with inadequate airflow across evaporator coil.

- Heat stress cracks in furnaces and frozen evaporator coils can occur when fan airflow is too low.

- ECM motor hunting and motor controller failures occur when static pressures are too high.

- Erratic thermal expansion valve operation happens when ECM motors are hunting for programmed airflow.

- Customers complain of high noise levels when variable-speed motors try to overcome high static pressures.

- Low fan airflow causes furnaces to cycle on high-limit switches instead of thermostats.

- You won’t achieve appropriate heating, cooling, and humidity control if fan airflow is way off.

- You can’t deliver proper levels of conditioned air to each room in a structure unless the equipment produces enough conditioned air to satisfy all the rooms.

PLEASE NOTE: For this article, we’ll assume the installed equipment is sized properly for the structure.

PLEASE NOTE: For this article, we’ll assume the installed equipment is sized properly for the structure.

If not properly sized, a more thorough technical analysis and design procedure is in order.

What’s the common culprit? Inappropriate fan settings and airflow restrictions that cause high static pressure.

What’s the solution? NCI’s ‘Air Upgrade‘ process makes sure the equipment is operating with the appropriate fan airflow levels. The air upgrade process attacks common equipment setup issues and airflow restrictions primarily found at the furnace or air handler. The process focuses on achieving proper fan airflow at the equipment, so it can operate as the manufacturer intends.

However, there is no guarantee that an Air Upgrade will get the air to where must go. That would involve more substantial work to optimize the duct system through testing, redesign, renovation, and balancing. A fully optimized and balanced duct system is the only way to ensure every room in the building is comfortable.

Six Ways Air Upgrades Enhance Business Profits

Here are six ways that adding Air Upgrades to your product offerings that enhance profits:

- Creates non-emergency work all year long

- Adds more billable installation hours

- Increases self-generated sales opportunities

- Provides higher average sale prices

- Enhances customer delight

- Enables positive customer reviews, testimonials, and referrals.

Let’s take a quick look at how each of these benefits enhance business profits.

Creating Non-Emergency Work All Year Long

Much HVAC work relies on extreme-weather conditions. When it’s very hot or cold outside, you usually have more work on your plate than you can handle. The urgency in your customer’s voice is loud and clear as they declare their situation a dire emergency. This ‘wait until it breaks’ customer service strategy makes it tough to keep crews busy year-round since equipment doesn’t break during mild-weather months.

Unapplied labor occurs when your team members sit on the bench, just waiting to get in the game.

The mild-weather months find your most valuable resource, your trained field staff, washing trucks, sweeping warehouses, painting walls, and ‘staying busy’ while producing no billable time. The Air Upgrade process identifies plenty of non-emergency work you can perform regardless of weather conditions. This additional work keeps your team on the field and off the bench, reducing unapplied labor and producing revenue all year long.

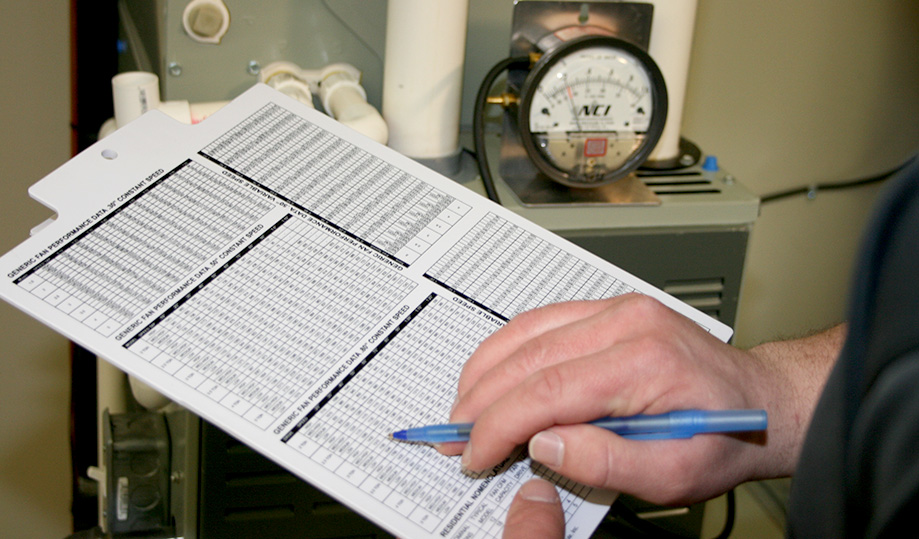

Static pressure testing is a key component of the Air upgrade process.

Adding More Billable Installation Hours

Some of the work associated with the Air Upgrade process is time consuming and is therefore avoided by many contractors. I can’t tell you how many times I’ve heard ‘working on duct systems is too labor intensive’ from contractors struggling to make ends meet.

Here’s a tip: ‘labor intensive’ translates into more billable installation hours!

Keeping your team productive (reducing unapplied labor hours) is key to your business profitability. The key to success is ensuring that this type of work is priced and managed properly so ‘the juice is worth the squeeze.’ Increasing billable hours for your installation team is never a bad thing, as long as it is profitable.

Increasing Self-Generated Sales Opportunities

Self-generated (proactive) leads are always better than emergency (reactive) leads. Why is that? Consider this truth: ‘He who identifies the problem, resolves the problem.’ Think about that and let it sink in for a minute. The person who identifies the problem is typically the person who resolves it. Don’t you want to be that person?

In the case of your customer determining their HVAC system no longer works (usually on the hottest or coldest day of the year), they are in control of resolving the problem. They may decide to call you, or they may decide to call your competitors. They decide, not you. If they choose to call you, your team must react promptly to the emergency or face the consequences.

Contractor-availability trumps customer-loyalty in an emergency.

The Work is Yours

What if you were the one identifying the problem? Does that mean you get to resolve it? Most of the time, it does. Think about a typical service call. When you diagnose the problem and present your recommended repairs, don’t you get that job most of the time? Sure, you do.

The Air Upgrade process is a 100% proactive self-generated sales opportunity machine that you can turn on and off as needed. It all begins with a simple set of static pressure measurements that help you and your customer understand the current operational status of their HVAC system. Based on this simple testing process, your self-generated sales opportunities are guaranteed to increase.

Generating Higher Average Sale Prices

Experience has proven that most installed HVAC equipment does not operate as designed by the manufacturer. Consumers have learned to ‘live with’ the consequences and believe that ‘ultimate indoor comfort’ is unattainable. This provides a great opportunity to offer more value to your customers.

When you offer more value to your customer, you earn more money.

The typical HVAC contractor focuses more on ‘swapping boxes’ without considering how well the rest of the system is functioning. Through the simple static pressure testing associated with the Air Upgrade, you demonstrate your commitment to ensure the customer gets everything they’re paying for. This added value always results in higher average job prices.

Enhancing Customer Delight

Customer satisfaction used to be a good goal, but no more. Your customers are much more demanding today. Thanks to Mr. Google, they know even more about what’s available to solve their problems than some contractors. In addition, the new HVAC equipment you install is much more demanding. You must install it properly to deliver the benefits promised by the manufacturers.

When your customers are ‘more than satisfied,’ they’re ‘delighted.’

A large base of delighted customers is one of the most powerful ways to enhance business profitability. Delighted customers don’t shop around for better deals because they’re pleased with their relationship with your company. When you employ the ‘measure, don’t guess? Air Upgrade approach, your customer continues to be delighted with their indoor comfort system and the company that’s maintaining it!

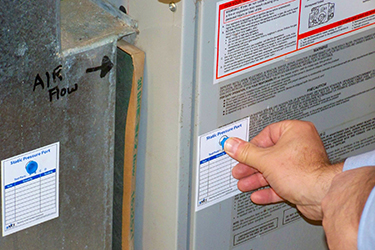

Installing test ports make taking static pressure measurements faster and safer.

Encouraging More Positive Reviews, Testimonials, and Referrals

Your growing base of delighted customers will help expand your business if you just ask them. When customers acknowledge that real value has been delivered through the Air Upgrade process (you reduced their long-standing dust problem, or solved their high electric bill issues, or made the master bedroom more comfortable, or reduced the noisy fan operation…) it’s your signal to ask for their help.

When you help someone get what they want, they’ll help you get what you want.

If you proactively measure the performance of your Air Upgrade enhancements by looking through the eyes of your customer, they’ll happily post positive online reviews, write glowing testimonials, and refer your business to their friends, family, and acquaintances. The key is to be intentional about it ‘ don’t let it ‘just happen.’ Be proactive and the results will follow. Those positive reviews, shining testimonials, and referrals are the best fuel for your sales engine.

Air Upgrades Can Change Your Life

Sometimes, the simplest things are the most powerful. That’s truly the case when it comes to Air Upgrades. When you can create non-emergency work all year long, add more billable installation hours, increase self-generated sales opportunities, enjoy higher average sale prices, enhance customer delight, all while garnering more positive reviews, testimonials, and referrals, why wouldn’t you?

To learn how to implement the Air Upgrade process in your business, attend NCI’s Airflow Testing & Diagnostics Implementation Workshop.

Recent Comments