Abnormal combustion conditions include the following:

- Rust is an indicator of flue gas spillage. Carbonic acid in the flue gas contacts metal surfaces and begins to create rust and corrosion and can lead to chassis issues and possible carbon monoxide (CO) leakage

- White powder forms as the carbonic acid in flue gas comes in contact with a surface and then dries

- Cracked heat exchangers are not normal. They occur because of excessive heat that causes metal to expand and contract beyond its design considerations and limits. Common causes are excessive fuel and or low airflow across the heat exchanger. In some cases, these units cycle on the high limit switch or worse. Sometimes the technician either replaced or tampered with the limit just to keep the unit running.

Regarding GAMA Tables, here are more truths:

- Computer programs are no more than a code that instructs a computer, application, or software on how to perform without predetermined assumptions and do not consider many obstacles installed or encountered in the field

- A methodology is merely “a contextual framework” that does not provide solutions for given situations. GAMA Tables are not based on any actual field tests or conditions.

Toolset

Changing the mindset includes education of the true dangers and precautions of combustion. Toolset begins with personal safety and awareness of your surroundings when working on combustion appliances. Having a personal CO monitor is the best way to assure that you and your customers remain safe when installing, testing, and repairing these appliances.

For many years I worked in large machine and boiler rooms and management never explained the importance of monitoring work surroundings. The scary thing is many of us have been exposed to high levels of CO many times. We were not aware of the real reason why we had a headache or an afternoon of nausea and slight dizziness. We assumed the cause was from something else like not eating a good lunch, or being too tired etc.

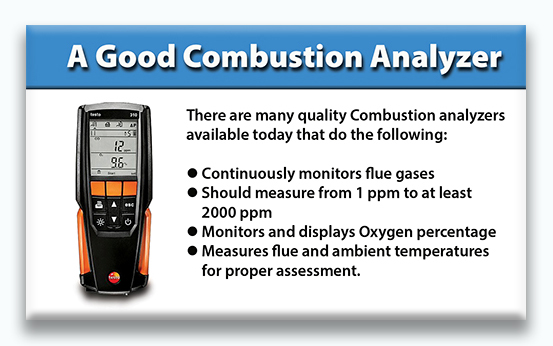

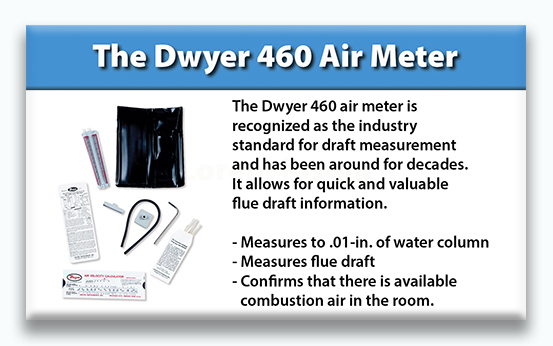

Changing the toolset just begins with personal safety. It forces us to look beyond the classic approaches to service and installation by acquiring the proper tools and instruments to properly test, assess, and adjust for proper combustion. This begins with a simple draft gauge and a quality combustion analyzer.

Click Below for the Next Page:

Recent Comments