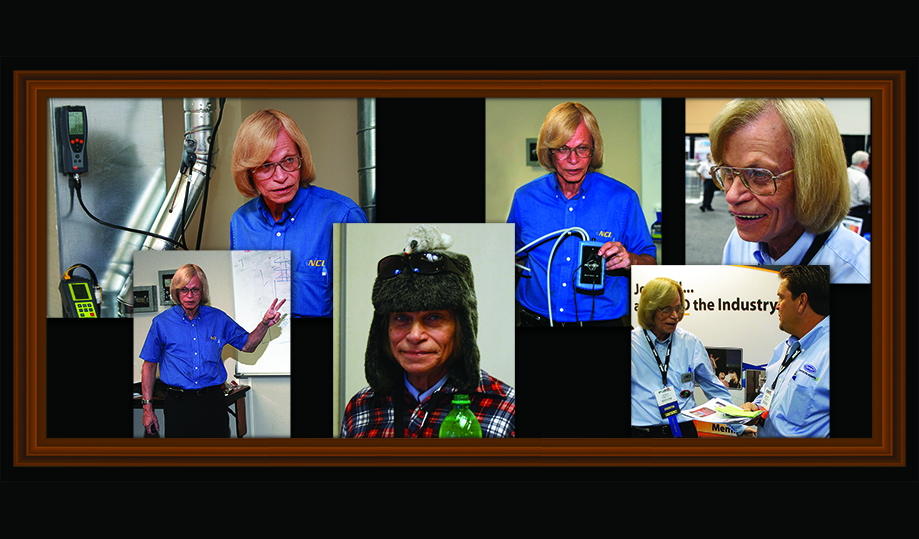

For decades, one person has searched for the truth about combustion and its impact on safety, health, and efficiency. His natural curiosity and analytical mind founded the modern age of combustion testing, analysis, and carbon monoxide (CO) safety. His name is Jim Davis, and, in my opinion, it’s time we recognize him for all his contributions to the HVAC Industry.

Initially, Jim started working for an HVAC distributor in Cincinnati, OH. In 1978, he was a counter guy who sold a new test instrument to his commercial and industrial customers. It was a combustion analyzer, which cost about as much as a car. Jim Davis didn’t come into this industry with an engineering degree. However, he brought his strongest skill set – his curiosity. This trait became the foundation of legends. So much so that, back in 2015, National Comfort Institute President Rob Falke wrote an article for Contracting Business magazine called “The Curious Captain CO.”

His early days in the industry were humble ones. As a counter guy, Jim found that the customers he sold analyzers to had no idea how to use them. So started the journey of Captain CO.

Challenging Times

For Jim to succeed, he had to teach his customers how to use the analyzers. So, he looked for resources where he could learn about their use but found that there wasn’t much available in the way of instructions.

Not one to give up, Jim Davis started to teach himself how to use analyzers. He sought out and began reading books, some of which were hundreds of years old! Jim also started digging into the concepts behind combustion engineering. He started researching. And his reoccurring question was always to ask ‘Why.’

In fact, Jim asked ‘why’ and ‘what if’ questions about everything. He then followed up those questions with testing and more why questions.

For example, when he discovered rising carbon monoxide, it was purely by accident. Instead of doing what everybody told him, he broke traditional testing practices and left the analyzer probe in the flue.

Back then, the CO measurement wasn’t digital. Instead, it was an analog tube-style indicator with a length of stain that changed when CO went up. In this case, the indicator went from showing no CO to filling up the whole tube. Jim wanted to know why that happened. So, he changed out the tube, and the length of stain instantly filled the tube again.

Jim called the test instrument manufacturer to find out why this happened. Unfortunately, they didn’t know. Fortunately for the entire HVAC industry, Jim wanted an answer. He started deep diving into his research until he discovered what was happening: the combustion process was deteriorating inside the equipment, leading to excessive CO production.

More than 40 years later, most of our industry still fails to recognize this phenomenon and continues to stress single-point CO measurements after 10 minutes of equipment operation.

In my opinion, this is one of Jim Davis’s most significant contributions to the HVAC industry.

Click Below to go to the Next Page:

Well done, David! I have met you , but never have I had the pleasure of meeting Mr. Jim Davis.

Although I have read and paid very close attention to all Jim has to say whenever I get the chance, (the voice of experience on Bryan’s You Tube Round Table), I still desire to learn at his feet. Even after 48 years in this trade there is more to learn.

I find myself on the other side of the fence these days doing tech support and training a new generation of technicians and always wanting to train them right.

I attended a class with Jim a number of years ago. He said something like,”The combustion air does not know that he needs to come in the bottom and out the top opening required by code.” This is so simple, but so very accurate. It is an extremely low bar set against a science that is intended to save lives.

It doesn’t matter what a tradesman looks like, it matters that he does good work. The industry is full of humble-looking geniuses that make magic happen daily. Jim is one of these.

Very good article! Thanks for writing it, David!