In nearly all the problematic homes, we managed to correct issues or significantly reduce their negative impacts by first seeking to understand the system design, its goals, equipment function and operation, and installation. We compared the results of our testing measuring that conflicts with the design and its intent. That enabled us to correctly diagnose what was happening and create a scope of work to facilitate repairs.

Ice Banking

With utility costs and tiered peak usage rates impacting commercial, industrial, institutional, and military facility operating costs, attention is being focused on new approaches to energy savings. HVAC industry manufacturers have worked hard to make the equipment we use more efficient, but more must be done.

Many universities and emerging technology labs have been working on various ways to reduce operating costs. One idea was to use lower-cost tier times at night to generate energy that could offset daytime electrical costs. It is more effective to operate the equipment during cooler nighttime temperatures. This is called Ice Banking.

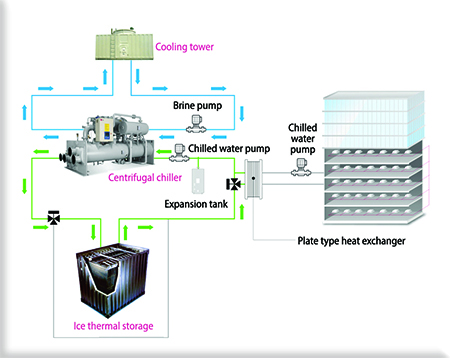

Ice banking can effectively offset space and production cooling costs, especially in hotter climate areas. It is pretty simple in theory. The goal is to divert the chilled water from the cooling coils and equipment to a storage device. That device will allow you to use stored cold energy later to help offset operating costs of large plant systems.

This technology has an unlimited number of sizes, configurations, and applications. It comes with more complex scopes. It can be even more reliant on the installed job being correctly balanced to achieve design and on investment goals. These systems can range in size from small five-ton packaged units to extremely large district-type built-up systems rated for thousands of tons of cooling.

Ice Banking Applications

Simple ice banks have been used for years in soda and beer dispensing systems. Why? They have an exceptional ability to recover to high-demand flow periods. These dispensing systems are relatively cheap to purchase and operate. They build up a bank of ice at night or during slow periods, and as the high-demand period starts, the ice begins to melt, maintaining product temperature. The system rebuilds ice during slow or nighttime periods.

Ice Bank systems used in the commercial and industrial sectors are vastly larger and more complex, using equipment from cold plates, storage tanks, and silos to large farms of ice storage tanks and devices.

Some Ice bank systems are so well engineered and balanced that the mechanical cooling systems may never operate during daylight hours except for high-demand periods. Some use balls filled with water that freezes in a brine or glycol solution pumped through the system.

Others use frozen eutectic salt and complex ice solutions that remove heat from whatever it serves. In this way, ice banks save wear and tear on chiller systems and shift power consumption to non-peak hours. Oh, and there is a bonus in that ice banks act as effective redundancy to the facility.

Click Below for the Next page:

Recent Comments