- Supply Plenum was restricting airflow

- Return Air Drop was restrictive, and the filter was open to the attic

- The Evaporator Coil was only an up-flow coil

- The Supply Trunk was undersized for the east side of the house (Master/Storage room and playroom)

- A dirty Blower Wheel

- The furnace was short cycling, going off on limit due to low airflow, restrictive supply/return, and bypass humidifier on return

- Smelled gas – found numerous gas leaks by the furnace.

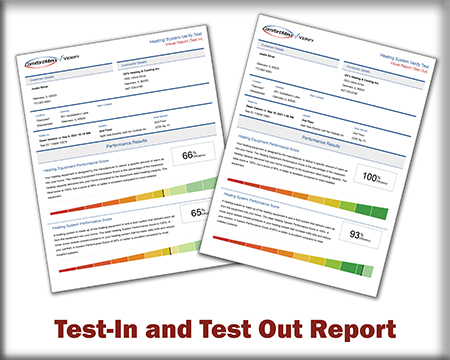

Along with this report, I also attach a “Test In” Visual Report from ComfortMaxx™. ComfortMaxx is a third-party software-based system evaluation and verification test. Using this software, I found that the Silver residence had the following:

This system required a fan airflow of 1,200 CFM, but I measured only 658 CFM. This brand-new system only performed at 55% of the required fan airflow.

GV’s Evaluation and Solution Proposal

How many times do we go into a home and have tunnel vision? We only see what is in front of us. I want to give a shout-out to NCI’s John Puryear, who, during a class he was teaching, mentioned that just because you see a furnace in an up-flow position, it does not mean it has to stay that way. He said, “We have to go into these homes and open our vision to a new perspective.”

In this situation, I did just that at the Silver’s home.

The furnace “room” was only 7 feet wide x 7 feet deep x 5 feet 2 inches high, After our evaluation, I knew the way the furnace was installed was not working. In this case, there was more room horizontally than vertically.

We needed to uninstall the furnace, evaporator coil, and ductwork in the utility room. The good news was that Silver’s furnace and air conditioner were sized correctly. The only piece of equipment GVs had to replace was the evaporator coil because it could not be installed horizontally.

No More Blowing Hair!

By re-installing the furnace in a horizontal position, adding a new supply plenum, increasing the supply trunk to the east side of the home (main suite, storage room, and playroom), adding a properly sized return duct, installing a new automatic humidifier, sealed filter cabinet, and sealing all the ductwork, we drastically increased this system efficiency.

The ComfortMaxx “Test Out” scored a Heating Equipment Performance Score of 100% and a Heating System Performance Score of 93%. The system was now delivering 1,139 CFM!

Plus, our solution eliminated the excess attic pressure. We no longer have blowing hair!

Dawn Mroczek is the comfort specialist at GV’s Heating & Cooling in Buffalo Grove, IL. In 2007, she moved into the sales position. She is certified in Commercial Air Balancing, Duct System Optimization, and was recognized as one of the ‘Wonderful Women in HVAC Sales’ with Sharon Roberts. She is also the 2020 recipient of NCI’s High-Performance Sales Excellence Award. You can reach out to her with questions at ncilink.com/ContactMe.

Recent Comments