Have you ever read through the manufacturer’s accuracy specifications for a manometer? Did you understand them well enough to know if the accuracy was good enough for the measurements you needed? Are you aware that even though you can see a stable number on the screen that looks like any other good measurement, it could be so inaccurate that you might as well be looking at a random number generator?

Every HVAC technician’s tool bag should have a manometer in it. Techs need to measure static pressure in ducts, gas valves, rooms, and the combustion appliance zone (CAZ), to name a few. For each of those measurements, a certain accuracy is required to be sure you have a useful measurement.

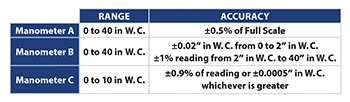

Manufacturers have different ways of specifying the accuracy of their instruments (see Figure 1). They are not easy to compare just by reading them! It looks like “Manometer A” might be the most accurate because it says 0.5%, and the other two say 1% and 0.9%, which are larger percentages. But that does not tell the whole story.

Confusing right? If we break down those specifications, they consist of just two types of errors or uncertainties:

- Errors that are a fixed pressure across the measuring range

- Errors that are a fixed percentage across the measuring range.

Three Common Measurements

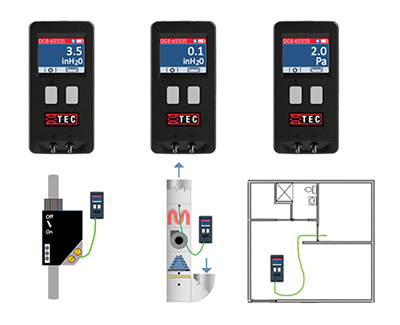

To unravel the meaning of these specifications, let’s use them to estimate the accuracy of three common measurements (see Figure 2) an HVAC technician should take.

- A gas manifold pressure of 3.5-in. W.C.

- A supply duct plenum pressure of 0.1-in. W.C.

- A bedroom pressure of 0.01-in. W.C. (Room pressures are more commonly measured in Pascals (Pa), but we’ll do everything in inches of water column (in W.C.) to keep it consistent. 0.01 in W.C. is about 2.5 Pa, a common pressure for a bedroom in a house).

The Math for Accuracy

- Let’s have a look at the chart on the next page (Figure 3). If you study this chart, you will see the three manometers applied to our three use cases. Green indicates that the manometer’s measurement accuracy is good enough to be useful. Red is not accurate enough, and yellow is probably useful, but could occasionally be misleading.

In the first scenario, we measure gas pressure with Manometer “A.” The manufacturer’s specifications are 0.5%. But any time you see a percentage, you should ask yourself, “Percent of what?” In this case, it’s a percent of Full Scale. For this manometer, the full-scale reading is 40-in. W.C., and 0.5% of 40-in. W.C. is 0.2-in. W.C. So, this is really a fixed pressure error; the error is ±0.2 in. W.C. at any reading.

Click Below for the Next page

Recent Comments