The sensible heat formula is:

Sensible Heat = CFM x ‘t x 1.08

- CFM = Airflow measured at the fan or supply registers

- ‘t = The dry bulb temperature change

- 1.08 = A multiplier based on standard air conditions.

The total heat formula is:

Total Heat = CFM x ‘h x 4.5

- CFM = Airflow measured at the fan or supply registers

- ‘h = The enthalpy change in Btus per pound of air

- 4.5 = A multiplier based on standard air conditions.

Once you calculate sensible heat and total heat from a cooling system, you can estimate latent heat removal by subtracting your results from the two formulas. This is quick and keeps the process simple.

Your imagination will determine how far you can apply these formulas. The simplest place to master their use is at the equipment to see how well it’s operating. From there, you can move to the duct system and see how well it works. With more advanced testing, you can estimate duct system losses and gauge the influence of outside air ducts and economizers.

The application of these formulas is the first step to assuring a system performs as designed. The second step is to compare your Btu measurements to the equipment’s rated Btu output. This is where you score the performance of an installed system.

Score Installed System Performance

Once you have the Btu measurements from an operating system, you need to track down the manufacturer’s equipment-rated output. If you’re testing a furnace in heating mode, look at the rated Btu output on the furnace nameplate. This is the number that you will compare your measurements to.

If you measure in the cooling mode, you will need to gather more information than what’s on the nameplate.

You will need:

- Outdoor air temperature at the outdoor unit

- Dry bulb temperature entering the indoor coil

- Wet bulb temperature entering the indoor coil

- Airflow across the indoor coil.

With these four variables, you can determine the equipment-rated Btu output capacity at those conditions.

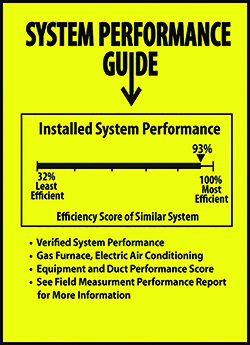

Once you have a system’s measured Btu output and equipment-rated Btu output, you divide the two to come up with an installed system performance score. National Comfort Institute, Inc. (NCI) introduced this simple test method to determine installed system performance over 17 years ago ‘ the System Efficiency Ratio or SER.

To score a cooling system you would use CSER (Cooling System Efficiency Ratio). To score a heating system, use HSER (Heating System Efficiency Ratio). In 2020, we refer to this method as a System Performance Score (SPS).

A Trip Down Memory Lane

To expand on how to score installed system performance, I thought it would be fun to look at the first test I did with this method back in the winter of 2003. Little did I know how much we would come to use these principles in the following years.

The home we tested in Central Kentucky had a 92% efficient, 100,000 Btu input, horizontal gas furnace. If everything was perfect, the duct system should deliver 92,000 Btus (92% of 100,000 Btu) of sensible heat into the home.

That would equal an HSER of 100%. Since we tested in heating mode, we used the sensible heat formulas. To complete it, we needed to gather system airflow and ‘t.

Our first step to determine heating system performance, or HSER, was to measure total supply register airflow. We used a TSI balancing hood and measured airflow from all the supply registers in the home. Once we had our readings, we added them together to get the total delivered supply airflow of 1092 cfm. This is the first piece of the sensible heat formula.

Click below for next page:

Recent Comments