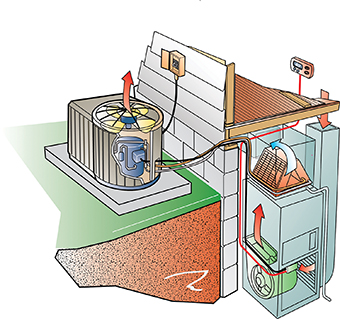

Next, we determined the system ‘t. With an accurate and fast digital thermometer, we measured the average supply register and return grille temperatures in the home. We chose three supply registers across the duct system to take our readings and then averaged them. Our average supply temperature was 120.3? F.

We also took two return grille temperatures in the same manner and averaged them. Our average return grille temperature was 71.7? F. To get our system ‘t, we subtracted 71.7 from 120.3 to find a 48.6? F system temperature change (120.3 – 71.7 = 48.6). We now had the second piece of the sensible heat formula.

Next, we needed to determine delivered Btus from this system into the home. We plugged our total supply register airflow and system ‘t into the sensible heat formula. We found the system was only delivering 57,317 Sensible Btus (1092 x 48.6 x 1.08 = 57,317).

To determine the heating system’s performance, we divided our system measured Btus of 57,317 by the furnace-rated output of 92,000 Btu. This meant the system was operating at 62% of its potential (57,317 – 92,000 = 62%). This level of performance was unacceptable and not what our customer expected to see. Unfortunately, it’s common in our industry because it remains hidden without measurements.

The good news is, because we DID do these measurements, we were able to ‘fix the customer’ with a complete duct renovation which greatly improved the overall system efficiency.

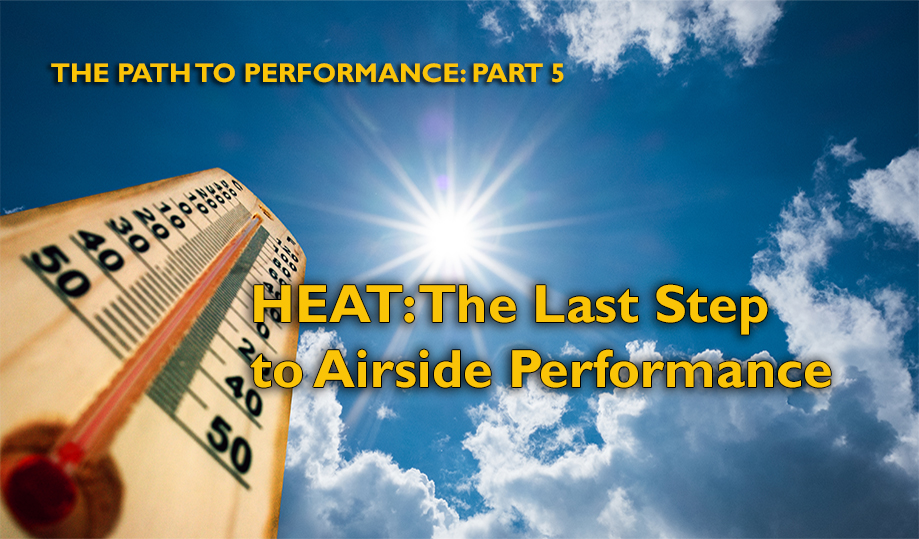

Obstacles in the PATH

When we first began to measure Btus and rate system performance, we didn’t know the questions to ask until after we tested. It’s impossible to account for every variable before you start. Don’t let fear of the unknown prevent you from taking one step at a time.

If we had not mastered the principles of pressure, airflow, and temperature, I don’t know if we would have been successful at implementing Btu measurement.

Having that foundation is important to you because there are a lot of moving pieces that can frustrate you. You learn by doing, so get out there and start testing. You must get your hands dirty to master these skills.

It’s important to understand that the equipment must be right before you can get the system right. If your combustion and refrigerant charge are off, there’s no way you can get the Btus even with proper airflow.

Start with your installations, just like the other steps on the Performance PATH, and find what works and what doesn’t. We put the steps in place in the NCI training classes, but every company must use each step in a way that works for them.

Walk the PATH

In the next article, we’ll look at what it takes to walk the PATH to Performance. We will revisit the importance of small steps and what it takes to build consistent habits, and what you need to know to add performance to your daily services.

Recent Comments