Diagnose System Temperature Readings

Let’s say you have a duct system installed in an attic. It is common in many parts of the country for attic temperatures to reach 130′ to 140’F in extreme summer conditions. Combine that with ducts in the same attic space carrying 55’F conditioned air, and you have a recipe for an uncomfortable building. That’s a 75′ to 85’F ‘t (temperature difference)! Ceiling insulation is often R-38 while duct insulation maxes out at R-8. There’s a problem with this thinking.

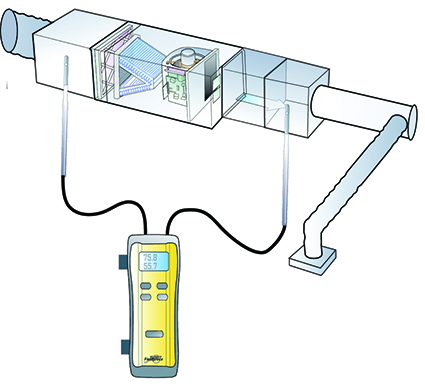

You can use system temperatures to measure duct temperature gains. All you need are four temperature readings. Make sure the equipment has been running for at least 10 minutes before testing. Start at the air handling equipment and measure supply and return air temperature to determine equipment ‘t. Next, measure the farthest supply register and return grille air temperatures to determine the worst-case system ‘t.

First, in cooling mode, find the equipment temperature drop. Subtract the equipment entering air temperature from the equipment exiting air temperature.

Next, calculate your supply duct temperature gain. Subtract the equipment exiting air temperature from the farthest supply register air temperature.

Then, find your return duct temperature gain. Subtract the farthest return grille air temperature from the equipment entering air temperature.

Finally, add together your supply and return duct temperature gains to find total system duct gain.

For example, let’s say you measure a cooling system with a 20? ‘t across the equipment and a 10? ‘t across the duct system. That would be a 50% duct gain (10? – 20? = 50%)! If your equipment is rated at four tons, it would be the equivalent of a two-ton unit because of that duct temperature gain. You won’t see this unless you measure system temperatures and equipment temperatures.

In heating mode, the principles are the same, but the temperature locations in these formulas flip flop.

The most applicable repairs for duct temperature gain are to add duct insulation and seal duct leakage. Be careful as you choose from various insulation options available. Some insulation types offer exaggerated promises but don’t perform in the field.

Obstacles in the PATH

As you move further along the Performance PATH, the obstacles you met with pressure and airflow are the biggest to overcome. If you’ve come this far, it’s all downhill from here. Two of the most common obstacles you will find with temperature are:

- Testing too close to a heat exchanger or cooling coil

- Taking too much time between your readings.

Both issues can cause your temperature readings to make no sense or look like the equipment and/or the system is operating better than they are.

Pay attention to these easy-to-correct obstacles.

Our Last Step

Heat is the last step on the performance path. It is the combination of temperature and airflow and the true measurement of installed HVAC system performance.

In the next article, we’ll look at what this step has to offer you and how it moves our industry beyond selling boxes to providing solutions.

Recent Comments