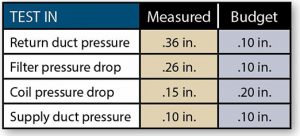

Testing In

First, before starting the job, I measured static pressure to determine what system components needed renovation. These are the readings I measured and recorded.

First, before starting the job, I measured static pressure to determine what system components needed renovation. These are the readings I measured and recorded.

I compared static pressure for each component to its corresponding budget. Whenever measurements exceed the budget, a renovation is likely. When you find the static pressure below the budget, I assumed that you leave it alone.

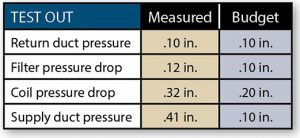

Testing Out

In the world of Performance-Based Contracting’, it is standard practice to test out after your renovation work is completed to ensure you achieved what you set out to do. Testing-out the system was my next step and felt the outcome was going to be good.

In the world of Performance-Based Contracting’, it is standard practice to test out after your renovation work is completed to ensure you achieved what you set out to do. Testing-out the system was my next step and felt the outcome was going to be good.

Believe me, it came as a shock when the test-out measurements told a different story. Return duct and filter pressure drop showed huge improvements. Keep in mind, I didn’t touch the supply side besides sealing plenums and collars. So where did the high supply static pressure come from?

What I Missed

Despite being well trained and certified in this work, I didn’t quite remember everything I learned. One of those things is Fan Law 2. In essence, that law states that static pressure squares with an increase of airflow.

Confused? Look at the numbers again. There’s a reduction in static pressure on the return side (filter drop, return pressure). Remember, anytime static pressure decreases, airflow increases.

Confused? Look at the numbers again. There’s a reduction in static pressure on the return side (filter drop, return pressure). Remember, anytime static pressure decreases, airflow increases.

Why did the return duct and filter pressure drop decrease? Because when you increase the size of a duct or filter, it’s easier for the fan to move air through the system.

Why did coil pressure drop and supply duct pressure increase? This happened because removing the pressure on the return side allowed the fan to circulate more airflow.

Now that the fan airflow increases, more air moves through the coil and supply duct causing higher static pressures. As it turns out, the coil was dirty and had undersized supply ducts. I couldn’t tell that from the test-in because of low fan airflow.

Outcomes and Lessons Learned

As trained professionals, it’s our job to correctly assess and test each situation to improve the quality of life for all parties involved. Part of that is learning from both your training and your mistakes. We have so many tools at our disposal and it’s easy to forget them, especially if we are not using them on a daily basis. In this case, that tool is Fan Law Two. If I had remembered it, I could have better served my customer.

Life in the field is all about continual learning and this was the best learning experience I could have had. It was the first and last time I made this mistake. From that point forward, I always remember that using the fan laws helps to predict outcomes.

Continue testing my friends.

Casey Contreras is a trainer and field coach for National Comfort Institute (NCI). If you would like Casey to email you a link to a free App for your phone to quickly determine the airflow of residential fans in the field, email him at caseyc@ncihvac.com or call him at 657-227-6188.

Recent Comments