Also, NCI has Generic Return Grille CFM Recommendations. Please note that NCI recommends you use metal adjustable elbows or Flex Duct Saddles instead of bending the flexible duct.

If you find an attached media filter; NCI recommends using a minimum size cabinet — 25-in. x 20-in. x 4/5-in. (good up to 1200 CFM per three-ton condensing unit. If bigger, add another filter cabinet).

Make sure there is a six to 12-in. transition from the media cabinet to the air-handling equipment. Return velocity should be between 300 to 400 FPM. NCI suggests using a maximum filter pressure drop budget for Gas Furnaces of .10-in. w.c., for Air Handlers, .15-in. w.c.

- If you have multiple returns Do Not Forget to add Air Volume Control Dampers to balance the return air duct upon completion. This is necessary to balance the HVAC system.

Make Good Choices on the Supply Side

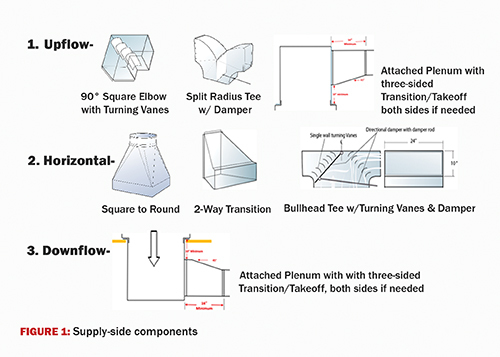

Supply Side of the HVAC System: Are all the Supply duct components sized correctly? Let’s start with the first supply fitting off the air-handling equipment. Depending on the layout; upflow, horizontal or downflow, here are some suggestions (See Figure 1).

- All Figure 1 fittings may be used interchangeably, in most situations. Another reference to consider using is NCI’s Duct Fitting for Measurements Worksheet. It’s designed to help contractors who need fittings but do not have sheet metal shops and outsource to a sheet metal fabrication shop.

- When it comes to your duct renovating process, upgrade the trunk duct as needed. In many cases, upsizing the first four to six ft. to handle all required airflow, then re-attaching or adding branches, can decrease static pressure significantly. Reseal ductwork with mastic and verify the duct wrap insulation is rated at a minimum R-8 or meets local building codes.

NOTE: ACCA Manual D suggests not to run any given size of trunk duct more than 24 ft. Then reduce to avoid friction rate and static pressure issues due to effective length.

- There is a SMACNA fabrication note about when to transition. Be careful not to decrease the transition/reducer size by more than 4-in. This lowers the pressure drop of the fitting and allows the required air to drop by at least 200 CFM. Review Tech Tip: Sizing for Low Pressure Drop Duct Fittings.

- Make sure all branches have volume dampers installed. This is necessary once you finish renovating and need to balance the HVAC system.

- When re-attaching branch runs, follow the Two-Foot Rule. NCI recommends upsizing the takeoffs by at least an inch if using round collars or saddle airtites. When installing takeoffs on a rectangular trunk, always use side or top takeoffs.

NOTE: Air pressure is always highest on the sides.

Click Below for the Next Page:

Recent Comments