As a High-Performance HVAC™ Contractor, you go the extra mile when a client calls about comfort issues in their home. At first, you think it’s a return issue since that is the number one repair when renovating a duct system.

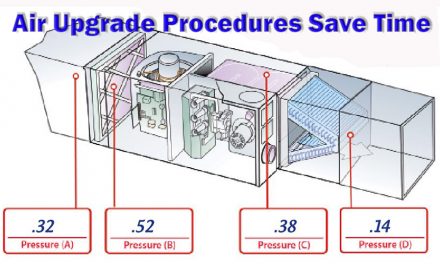

You then think about doing a TESP (Total External Static Pressure) test to check fan airflow and establish a baseline of how the HVAC system currently operates.

Once you’ve done the necessary initial testing, visually inspected and checked the existing duct system sizing, you can discuss how a duct renovating or Air Upgrade would increase fan airflow and decrease TESP in terms the customer understands.

On July 1, 2019, this magazine published an article named “Improve System Performance Using the Two-Foot Rule.” I wrote it because it was something I was taught in my early career by a grizzled old sheet metal mechanic who wanted me out of his hair. I have tested it and proven it works because it’s based on basic airflow principles. This is a follow up to the part of that article that discussed installing takeoffs 18 to 24 inches On Center when using an extended or reducing trunk line.

Let’s assume that as a high-performance contractor, you have a process/protocol you follow when you receive an airflow or comfort complaint from a client.

NCI has produced several “Tech Tips” to help with this process. First, let’s look at NCI’s “Guide to Enhanced Duct Installation.” This is a checklist you can use to train your installation crews as well as an evaluation tool after completing a project.

Make Better Choices on the Return Side

Things to consider so you can make better choices with regard to duct renovating work:

Return Side of the HVAC System: Verify return grille/filter sizing. (Remember 1 CFM In = 1 CFM Out). Review NCI Filter Sizing Procedure which states Required Airflow (CFM) ÷ Field Rated Velocity (FPM) = Required Area in Sq.Ft. for the air filter (Review NCI Tech Tip: Determining Maximum Allowable Velocity for a Return Filter).

- Size all return duct components for the required airflow using NCI Duct Sizing Tables.

Seal the joints with duct mastic and insulate appropriately. If using flex, pull tight (less than 4% compression) hang with less than ½-in. sag every 4 ft. (review Air Duct Council Green Book, Flex Duct Standard) and the NCI Tech Tip: Another Way to Hang Flexible Duct).

The components for a return upgrade include: Return Grille, Return Box/Can, two duct collars, flex/pipe, return plenum sized to handle no more than 300 to 400 feet per minute (FPM) in return velocity.

Click Below for the Next Page

Recent Comments