Rob Falke, President, National Comfort Institute (NCI)

The primary goal of NCI’s Air Upgrade Approach is to reduce the time it takes to test, diagnose, and sell HVAC system upgrades. This one-page report includes testing, diagnostics, a predetermined scope of work, and flat rate pricing. Let’s take a look at this testing and sales approach that many have adopted and benefited from.

The Bare Essentials

Many contractors want a way to find and sell system renovations that makes it easier to incorporate air diagnostics into their daily routines. NCI interviewed many contractors and studied mountains of data and created the Air Upgrade.

The Air Upgrade is a simple and affordable initial system modification designed to solve customer comfort concerns by improving fan airflow. Air Upgrades can be performed by any contracting firm of any size by involving maintenance and service technicians, as well as salespeople.

This quick and simple approach to air diagnostics can be incorporated into most service or change-out sales scenarios. The outcome is a basic system renovation that will increase fan airflow and improve HVAC system performance.

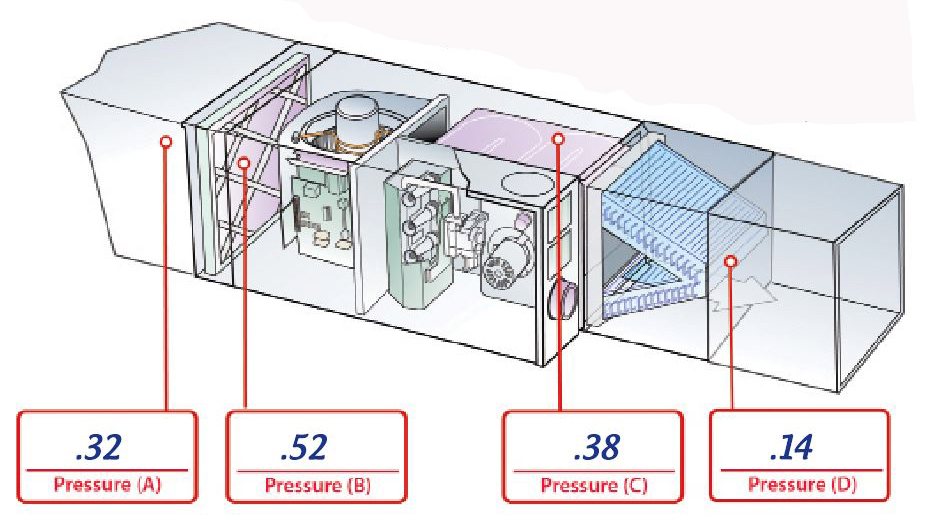

Figure 1: Example of static pressure measurements at the equipment.

Testing includes a static pressure profile and plotting fan airflow. This test information is used to diagnose low airflow causes and prescribe eight specific solutions. Of course, further testing and diagnostics can be added at any time.

Let’s review the six steps necessary to complete the process.

Step One: Gather Equipment Data

To accurately assess the performance of a system, first obtain minimal equipment information from the nameplate to determine the system size, required airflow, and static pressure requirements.

Step Two: Static Pressure Profile

Next, you take four static pressure measurements at the equipment. For a gas furnace with an external coil, take your readings before and

after the filter and before and after the coil. This test typically takes less than five minutes and provides important diagnostic information.

Step Three: Calculate Pressure Readings and Compare to Budgets

Using the four system pressures, you can determine the resistance to airflow through the system. These include total external static pressure, air filter pressure drop, coil pressure drop, supply duct pressure, and return duct pressure.

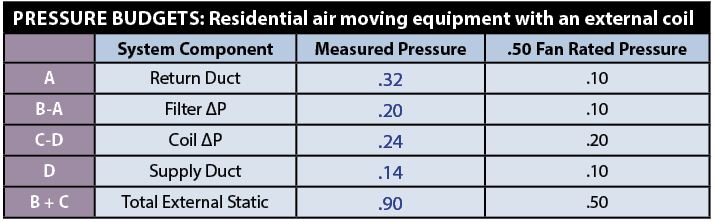

Then, based on a rated static pressure of .50 in., you diagnose the impact of each pressure with NCI’s static pressure budgets shown in the table (Figure 2).

The pressure of the return duct system in this example should not exceed .10 in. But the measured pressure is .32 in., showing the return duct is restricted three times what it should be. The return duct system needs some improvements.

The filter’s resistance is twice what it should be, further restricting airflow and deteriorating system performance. Replacing the restrictive filter with a less restrictive filter is a great solution.

Figure 2: Pressure Budgets.

Because of these system defects, the measured total external static pressure is .90 in. This is nearly double the fan rated static pressure. Under these conditions, the typical constant speed fan moves less than 270 cfm per ton.

As you can see from this test and calculation procedure, after less than 10 minutes of testing and basic diagnostics, this system is in trouble and would greatly benefit from air upgrades to improve fan airflow and system performance.

Step Four: Plot Fan Airflow

Since the fan generates 100% of the system airflow, knowing fan airflow is valuable in diagnosing and determining needed repairs. Fan airflow is typically found from the data you’ve collected and plotting it on a fan table.

In step one, you find the equipment tonnage and rated static pressure. In step two you measure total external static pressure. Now, all you have left is to identify the fan speed setting before you can plot fan airflow.

The easiest way to find fan airflow is using NCI’s AirMaxx Lite App?. You can download it for free at the Google (ncilink.com/AML1D) and Apple App (ncilink.com/AML1A) stores. NCI’s Generic Fan Tables are built into the app so you can easily determine the approximate fan airflow.

Or, you can secure the equipment manufacturer’s fan curves and plot the measured total external static pressure and the fan speed to find the fan airflow.

Then compare required system airflow to plotted fan airflow. It’s not uncommon to find fan airflow below 300 CFM per ton.

As you can see, this minimum testing and diagnostics quickly gets to the meat of system problems.

Step Five: Prescribe Solutions

Based on this abbreviated air diagnostics procedure, we discovered a universal set of repairs that solve many airflow problems detected from this testing.

The exact repair type varies with each system, as it does with any field installed system. We have categorized these repairs into two groups.

Typical Equipment Repairs:

- Upgrade filters to reduce resistance to airflow

- Adjust the fan speed setting

- Clean the blower and coil

- Verify fan airflow once repairs are complete.

Typical Duct System Improvements:

- Increase return duct capacity

- Increase supply duct capacity

- Basic duct improvements

- Reduce duct airflow loss.

Step Six: Price and Sell the Air Upgrade

Some companies are great at pricing equipment replacement, but haven’t developed a method to price duct system upgrades. Our research and contractor interviews helped create a flat rate pricing system for this set of repairs.

This flat rate pricing is based on typical cost for the repairs listed above. It provides adjustable labor costs, local material costs, profit margins, and variables contained in each job. The pricing can be adjusted by each contactor.

The objective of the Air Upgrade is to substantially improve the comfort and efficiency of an HVAC system and allow equipment to perform as intended by the manufacturer. It is most often used as an add-on sale at the time of equipment replacement where a total system price cannot be shopped.

When it comes to selling Air Upgrades, remember this: they have no set market value because testing and diagnostics create a unique product only you can offer.

Unique products result in a uniquely high profit that is worth the cost to you and your customer.

Recent Comments