Part 2: The Evidence Against Charge Adjustment

Ben Lipscomb

In Part 1 of this two-part series we examined the history of refrigerant charge adjustment (RCA) as an energy-saving measure in utility programs. We showed how the results have not been great. The impact of charge adjustment on energy use and savings is too varied, and program designs have not proven very effective at targeting only the adjustments that will save energy.

Does this mean contractors should abandon RCA as a practice altogether? No way! Getting the charge correct is critical to equipment performance, reliability, and efficiency. What we do on the airside effects the refrigeration cycle and vice-versa. If the answer isn’t to run around putting gauges on, calculating superheat and subcooling, and adding or removing an ounce of refrigerant or two on every unit we come across, then how can we ensure the refrigeration cycle is doing its part within the bigger picture of system performance?

What Can We Do?

If RCA can no longer serve as the foundation for tune-up and maintenance programs, how can energy efficiency (EE) programs realize the significant savings opportunity in improving the efficiency of existing HVAC systems? Putting programs aside, how should contractors approach refrigeration cycle diagnostics to best serve their customers?

We’ve gone deep into the reasons why RCA is a bad measure. Interestingly, we also find that each individual HVAC repair or tune-up item has its own set of issues that make them a poor choice if you look at them in isolation. Coil cleaning produces a marginal benefit that’s difficult to detect. Economizer repairs can produce either negative or positive savings depending on many variables such as damper position, changeover sensor type, and control settings. Duct sealing can produce negative energy savings by increasing fan energy and decreasing fan airflow.

To date, utility and regulator response to these challenges has been to dive deeper into the problems, with research. Furthermore, that research has become overly technical in a quest for a silver bullet. Tens of millions of dollars have been spent on this research producing thousands of pages of reports that are too technical for the average utility program manager or regulatory professional to act on.

Perhaps it’s time to reverse course. What if programs stopped prescribing specific measures, and simply allowed qualified contractors to do the work they feel needs to be done, and then prove it improved performance?

By prescribing a list of specific measures and attaching deemed savings and incentives to them, utility programs unintentionally limit the benefits that a skilled contractor can otherwise produce on a system. A restrictive list of measures tends to encourage business practices that focus on maximizing profit through low cost implementation of as many measures as possible. If instead, programs incentivized contractors to holistically measure and improve the system performance, the benefits could be dramatic.

Such an approach encourages contractors to look for value-added opportunities to improve performance and save energy. Savings become measurable by both contractors and utility programs, clearly supporting the value proposition for customers, utilities, and all stakeholders.

Measured Performance Improvement Potential

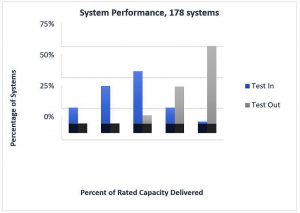

National Comfort Institute, Inc. (NCI) data for 178 commercial and residential systems, shown in Figure 2, indicates that 85% of existing systems deliver less than 60% of their rated capacity to the conditioned space. Each system was comprehensively tested, diagnosed, and renovated. ‘Improvements to ducts, equipment, and controls resulted in 75% of the systems delivering greater than 75% of their rated capacity to the conditioned space.

Figure 2: NCI System Performance Data

Meanwhile, advances in field test instruments and progress on standardizing test methods contributed to improvements in field performance testing accuracy and repeatability. The Western HVAC Performance Alliance (WHPA) and the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) are in the process of standardizing field data requirements[1] calculation procedures[2], and test methods[3] to measure and score HVAC efficiency and performance in the field.

Measuring system performance before and after a broad scope of system improvements are implemented provides direct data on efficiency and capacity improvements. Contractors can then use this data to estimate annual energy savings far more accurately than the estimates produced by typical deemed savings approaches.

NCI conducted a field data collection project to demonstrate this approach for a utility client and documented the results in a white paper[4]. We concluded that ‘Predictive savings informed by field-measured performance, and verified at the building meter, shows great promise in its accuracy, flexibility in application, and ability to reveal previously stranded energy savings.’

A Systematic Approach to Refrigeration Cycle Diagnostics Conclusion

Clearly the lackluster results and significant documented challenges show that Refrigerant Charge Adjustment (RCA) as a utility program energy efficiency measure must be called into question. RCA as a standalone measure, or as a foundational measure in tune-up or maintenance programs, is unlikely to lead to measurable energy savings or efficiency improvements, may lead to negative environmental impacts, and is not cost effective as an energy savings measure when properly performed.

The best path forward may be to take a step back, stop prescribing individual measures, and begin incentivizing Performance-Based Contractors to produce measurable improvements in efficiency and capacity.

While RCA has struggled to show even a 5% average improvement, a comprehensive renovation and tune-up program that rewards contractors for measured system performance improvements could regularly produce 20% to 60% increases in delivered capacity and efficiency. Advancements in field measurement instruments and standards enable contractors to accurately and repeatably measure efficiency and capacity in the field. Data shows that these measurements can be used to estimate energy savings with higher accuracy than traditional deemed approaches.

Ben Lipscomb is a registered Professional Engineer with over 14 years of experience in the HVAC industry including laboratory and field research, Design/Build contracting, and utility energy efficiency program design. He is National Comfort Institute’s engineering manager and may be contacted at benl@ncihvac.com.

[1] WHPA, 2016, CQI Standardized Field Data Specification for Commercial HVAC Installation (2016) http://ncilink.com/SFD

[2] WHPA, 2017, HVAC System Performance Assessment Calculation Procedures (2017) http://ncilink.com/SAC

[3]ASHRAE, SPC 221P – Proposed Standard Authorized June 29, 2016 (St. Louis)

Test Method to Measure and Score the Operating Performance of an Installed Constant Volume Unitary HVAC System http://ncilink.com/OpPerf

[4] NCI Lipscomb, 2017, Performance-Based HVAC Energy Savings

Recent Comments