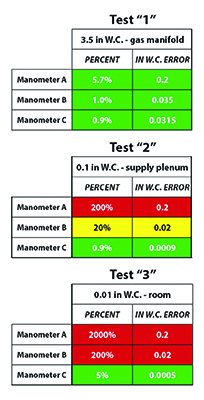

When we measure 3.5-in. W.C., it’s ±0.2-in. W.C. That means we expect the true pressure in the gas manifold to be between 3.3 and 3.7-in. W.C. when the manometer displays 3.5.

Now let’s also look at that as a percentage of what we’re measuring. To calculate the percentage, divide the error by the pressure we’re reading: 0.2 ÷ 3.5 = 0.057 or 5.7%. So our measurement would be 3.5-in. W.C. ±5.7%.

Let’s look at making that exact measurement with Manometer “B.” The specifications for Manometer “B” say that between 2 and 40-in. W.C., the accuracy is ±1% of the reading. Our reading is 3.5-in. W.C. One percent of 3.5 = ±0.035-in. W.C. So we expect the true gas pressure to be between 3.465 and 3.535-in. W.C. when the manometer reads 3.5.

Suppose we keep repeating this exercise using all three manometers. In that case, we must either convert an error in inches of W.C. into a percent, or convert a percent into an error in inches of W.C. Keep in mind that for Manometer B, it’s the opposite calculation above or below 2-in. W.C. For Manometer C, you must do both calculations, then pick whichever one is bigger.

Figure 3 shows the result.

Test 1: The Gas Manifold Test

Any of the three manometers would be accurate enough to give a meaningful measurement. The errors are all within a few percent of the measurement, so it’s not likely you’ll think the gas pressure is OK when it’s too high or too low, or think it’s a problem when it’s actually OK.

Test 2: The Supply Plenum Pressure Test

Now look at the supply plenum pressure. If measured with Manometer A, the error is 200% or 0.2 inches of water column. That could be a problem. Imagine your manometer reading is 0.1-in. W.C., when in reality, there is 0.3-in. W.C. in the supply plenum. It’s way too high! You’d think everything is OK when it’s not OK at all.

That measurement is so inaccurate that it’s not useful.

Next, let’s look at Manometer “B.” It tells us that the pressure is 0.1-in. W.C., but it could be as high as 0.12-in. W.C. or as low as 0.08-in. W.C.: plus or minus 20%. That generally tells you whether there’s a problem, but you wouldn’t be too confident about the readings.

The error will worsen if that pressure is lower at the next house.

Test 3: The Bedroom Pressure Test

Now for the hard one; a bedroom pressure of 0.01-in. W.C. In this example, you’re running the HVAC system at full capacity and measuring the pressure in each room with the door closed to see if there’s a clear path for the air to get back to the return.

In this example, only manometer “C” provides a reading accurate enough to be useful.

Click Below for the Next Page:

Recent Comments