This measurement determines if you need to add transfer grilles, jump duct, or a larger door undercut to allow air to flow back to the return when that door is closed. Manometer “C” will reliably tell you if that bedroom pressure is a problem.

The Whole Range

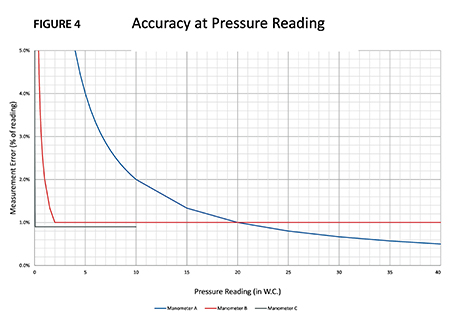

If we want to see the entire accuracy picture, we can make a graph (see Figure 4) to compare all three manometers over their full range.

This is easiest to do by looking at the measurement error as a percent of the reading. Here’s what that looks like:

This graph shows that at pressures above 25-in. W.C., Manometer “A” is the most accurate – the blue line has the lowest error. That’s because of that small percentage: 0.5%. But once you get down to 20.-W.C., the error is doubled to 1%. And when you go down to 1-in. W.C., the error doubles again.

In fact, it just keeps doubling every time the measurement goes down by half – that’s why it skyrockets at low pressures.

But it’s hard to see what happens at low pressures with manometers “B” and “C.” It looks like they shoot up to infinity really fast. But that’s not what’s going on.

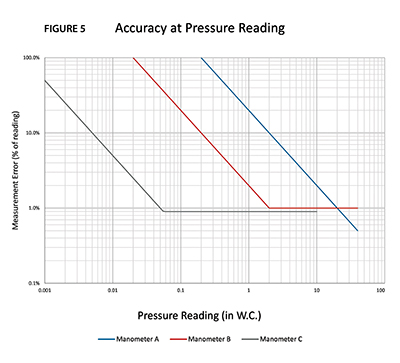

To see it, we must change the graph to a log scale (see Figure 5). You don’t need to worry about what that means; you need to know that this lets you zoom in on the lower pressures and higher errors.

Manometer “A” still shows an error of 1% at 20-in. W.C. and Manometer “B” still shows an error of 1% down to 2-in. W.C., and then it starts to go up.

But now we can see what’s happening with a tiny reading of 0.01-in. W.C., which is the bedroom pressure in our example. Manometer “C” has an error of 5% at that reading, and Manometers “A” and “B” are off the chart – over 100% error.

This graph shows us how all three manometers will ramp up when they get to that “fixed pressure” error at the lower end of their specifications, but they start ramping up at different starting points. We can also see that manometers “B” and “C” have a flat line when they get down to the “fixed percentage” part of the graph. Manometer “B” starts ramping up at 2-in. W.C., and Manometer “C” starts ramping up way down at 0.055-in. W.C.

Key Takeaways

HVAC technicians must measure many different pressures accurately enough to make confident decisions. But manufacturer’s specifications can be complicated and make it more challenging to know if the instrument is right for the job. Hopefully, this information will help you select the right manometer or know if the one you already have gives you reliable information to make important decisions about system performance.

Steve Rogers owns The Energy Conservatory (TEC), a manufacturing company specializing in home performance. The firm produces the MINNEAPOLIS brand precision diagnostic equipment and develops processes to solve building comfort, energy use, durability, and air quality problems. Steve can be reached at ncilink.com/ContactMe.

Recent Comments