Unfortunately, many smaller hydronic heating and cooling systems can’t be tested, adjusted, and balanced. Let’s take a look at what you can do to improve the performance of a water system that’s missing balancing fittings and valves.

Incomplete Hydronic Systems

Many hydronic systems are not designed or built for balancing. From one perspective, these systems are incomplete. Often, the budget for these jobs is low, so there is no design or specification. The installing contractor assumes it’s a self-balancing system.

But all is not lost. Each of these systems does include the most basic water system components. At a minimum, each has a pump, piping, and heating and cooling equipment. Don’t write the system off because the odds are you can improve it.

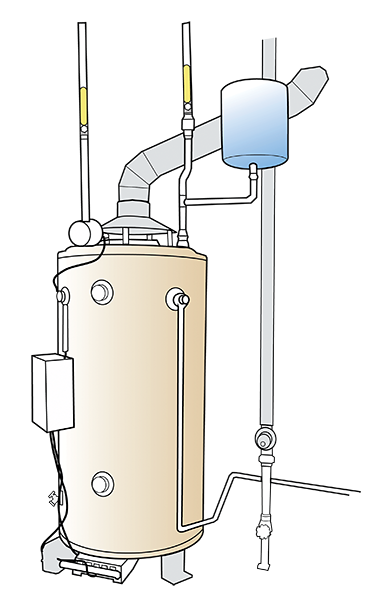

Typically, small systems may include a standard or tankless water heater or a small boiler. While most of these smaller systems move hot water, some may also move chilled water.

The equipment may include an air handler with a coil, baseboard units, a radiator, or some simple domestic water circulation system.

Identify What’s Missing

Normally systems designed and built for balancing include balancing values and test ports.

Test ports near the pump. When you balance a water system, one of the first steps is to measure pump pressures and plot water flow through the pump. Without these pressures, this test is impossible.

When you test a forced-air system, installing test ports is easy. You drill ⅜-in. holes through sheet metal in the duct or equipment.

Installing hydronic test ports in water piping is much more difficult. A water system of this caliber also lacks isolation valves. Without them, you’re unable to separate the piping from the pressurized system, and liquid squirts out when you install the test ports.

Balancing valves. A balancing valve lets you regulate system flow. Balancing valves also contain test ports that allow you to accurately measure and adjust the water flow through the system or a single system component such as a coil.

Any recommendations you make in the customer report should include installing balancing valves and test ports (also known as “Pete’s Plugs”). Installing these accessories provides access to water flow pressures in the pipe so that you can interpret system flow.

Inspect and Document the Water System

Your first step to discover improvements in a hydronic system is to inspect it and document your findings. Unfortunately, plans and specifications for smaller systems are rarely available, so begin by sketching a system schematic and taking photos of anything that may need repairs or upgrades.

Then, read and record the nameplate information on the pump and equipment. With the manufacturer and model number, you can go to the manufacturer’s website and download any specifications or engineering information.

Click Below for the Next Page:

Recent Comments