If you lay on your back in a swimming pool and float, that demonstrates positive buoyancy. If you sink, well that is negative buoyancy. In this case, we are talking about the density of combustion gases versus the surrounding air temperature. Atmospheric pressure and humidity also come into play.

This is logical if equipment is outdoors and only influenced by outdoor conditions. Some examples of natural buoyancy and atmospheric pressure are campfires and forest fires, and that doesn’t always work when the wind blows.

I have read many times that when you heat something, its molecules move faster and rise. Could that be why there are lids on barbecue grills, so our food doesn’t float away? The science says that heated items may expand, but they still must be less dense than their surroundings to rise.

Natural buoyancy might be predictable if something is only affected by one set of conditions. However, when installing equipment indoors, it is subject to two pressure zones, outdoor atmospheric pressure and the indoor stack effect of the building and/or building leakage. Then there is the resistance or pressure drop of heat exchangers, boiler sections, or baffles in water heaters. For hot combustion gases to rise up and out requires enough denser air to displace them and overcome this resistance.

Could it be that our forefathers were aware that a certain height or a minimum vertical rise is necessary to allow enough dense air to displace hot gases? Were they also aware that internal building conditions could affect this?

Lab Conditions Don’t equate to Field Conditions

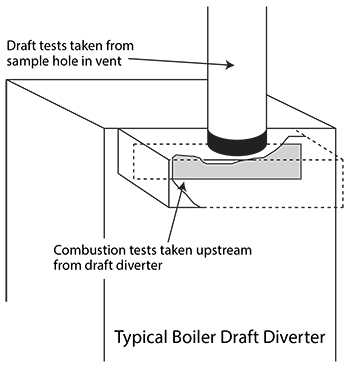

In the original installation instructions of mushroom down-draft diverters, it says to mount them at a minimum height on top of the equipment. This was usually 12 in., but could be less if the heat exchanger was taller. After installing the diverter, a tech performed a smoke test, and if the smoke did not pull in freely,he or she raised the diverter by another 12 in.

Much like today, this only simulates one set of conditions and — as we learn in the NCI Combustion Analysis and CO Safety class — this does not verify venting, only a venting action. Nonetheless, this was at least something to address existing environmental conditions back in the day.

Then manufacturers faced a new problem — a construction trend to lower the ceiling height in mechanical rooms. Equipment was now too tall to be installed with the movable mushroom downdraft diverter.

Attached or Built In?

Was it possible to build the drafthood into the equipment and shorten its height? Along came the attached or built-in drafthood of the 1950s and 1960s. Could you adjust them to overcome equipment pressure drop and internal building conditions? Like so much HVAC equipment, they were tested and certified in labs under ideal conditions that rarely occur in the field.

For example, drafthood equipment tested in a lab with controlled ventilation keeps the room neutral or slightly positive. They test it with five feet of vertical pipe and two elbows.

Click Below for the Next Page:

Nice article on draft diverter hoods.

I am interested in reading more about the white powder on flue pipes

I am retired now after working 45 years doing heating repairs. Twice I attended NCI’s combustion safety classes with Jim as the instructor. The thinking then was, if you didn’t measure, you didn’t know. Those words made so much sense to me.

The digital analyzer became the best investment that I could have made. It was expensive but very dependable and accurate. There were several times that I was able to track down and resolve CO problems.

By measuring, I found out that what I was seeing in a flame was at times not what the analyzer was seeing.

Following the protocol established for parameters that was provided by NCI kept me on course for not needing to make return calls on something that was serviced the first time.

It’s a good feeling to be able to say that you had a hand in finding problems that could have been serious enough to end up really bad.

Thanks NCI, thanks Jim

.

This is some great writing! I thought I knew draft hoods pretty well… I guess I do a bit better now. Thanks!