Most general interest newspaper or magazine articles about carbon monoxide (CO) will mention “CO leaks” as the cause of CO poisoning. These newspaper and magazine stories imply the venting system always has dangerous CO levels due. The reporters assume it’s only when CO gas “leaks” out that someone gets sick or worse.

Most of the public and many in our industry buy into this myth. However, it couldn’t be further from the truth.

Don’t get me wrong, maintaining acceptable CO levels in flue gases is necessary, but our industry rarely measures them. When was the last time a code official asked you to test flue gas CO levels in a system you installed? A tougher question might be, when did you last measure flue gas CO levels in a system you installed?

Let’s look at what you should know when you hear about “CO leaks.” Then, we will discuss how you can protect your customers.

What is a CO Leak?

Saying “CO leaks” is a misinterpretation of what’s happening during equipment operation. CO spills, it doesn’t leak, and it’s never acceptable when CO spillage happens. In fact, spillage indicates improper flue gas venting and unsafe equipment operation.

What if the flue gases never reached this opening or measured

10 PPM on a combustion analyzer?

Since CO can spill from equipment, why hasn’t there been more of an outcry to stop it, put safeties in place for prevention, and improve awareness? Instead, we tolerate situations that could put you and your customers in unsafe conditions.

How Does CO Spill?

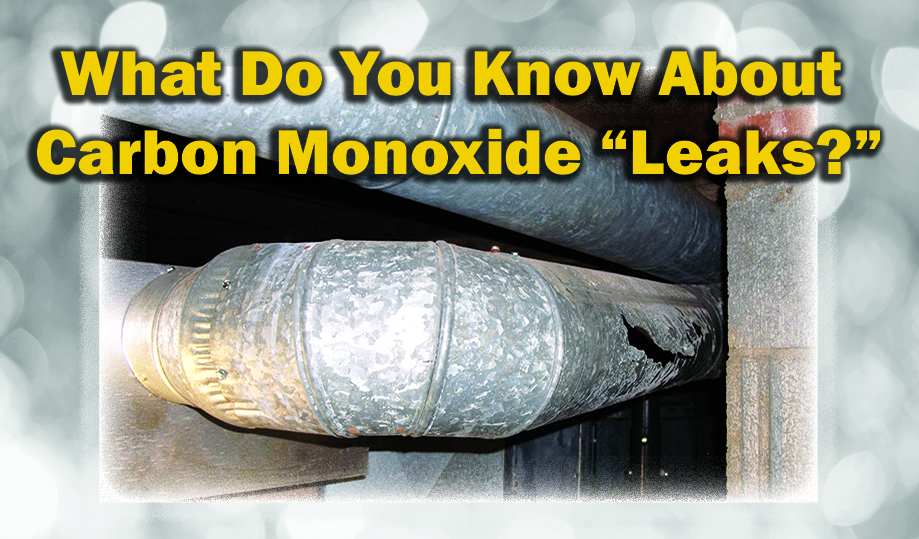

There are multiple locations where flue gases can spill from vented equipment. These locations include drafthoods on natural draft equipment, burner inlets, chimneys, and building openings.

It’s important to note that flue gases and room air can move into or out of these openings. They act as two-way streets for flow.

Draft pressure is the force that determines the direction of flow.

Uncontrolled draft can contribute to CO spilling from a venting system and any connected equipment. Low or excessive draft creates competition for airflow that causes carbon dioxide ( CO2 ) to build up in the burner compartment. CO2 is a heavier gas and one of the main byproducts of combustion. It starves equipment for combustion air as it builds up internally.

This CO2 build up is often the cause of what’s often misinterpreted as a CO leak. The equipment operates improperly when this condition exists, and it remains hidden if you test for it using current industry protocols. Two of those common protocols are:

- A single CO test in the equipment’s flue gas after 10 minutes of operation

- Use chemical smoke at the base of a drafthood.

Discovering CO Spillage

Are you aware that there are often visual signs indicating spillage is happening? Look for the following clues.

- Melted water pipe grommets or electrical wiring

- Rust around drafthoods

- Rust in the burner compartment

- Burner compartment discoloration.

Click Below for the Next Page:

Recent Comments