Some Statistics

For those who don’t know, Craig, Colorado is in mountain country, a five-square-mile city with seasonal temperatures that can range from -30F in January to 85F in July. On average annual snowfall in the area is a whopping 74 inches! Not a town for the faint-hearted to be sure. Still, the needs of the population for heating and air conditioning are demanding and Masterworks Mechanical has made it the mission to provide outstanding service to their client base.

For those who don’t know, Craig, Colorado is in mountain country, a five-square-mile city with seasonal temperatures that can range from -30F in January to 85F in July. On average annual snowfall in the area is a whopping 74 inches! Not a town for the faint-hearted to be sure. Still, the needs of the population for heating and air conditioning are demanding and Masterworks Mechanical has made it the mission to provide outstanding service to their client base.

The company serves both residential and commercial markets, which includes forced air and hydronic air conditioning, plumbing, service-repair-installation, new construction, as well as commercial refrigeration.

Updike explains they maintain 18 vehicles and have an optional box van with a lift gate. The fleet consists of seven service vehicles, seven installation vehicles, one box truck, a plow truck, and two owner trucks.

He says the mission is to provide the highest quality service and experience through top quality training and benchmarking improvements.

Success Based on Training

Over the years, all the field staff ‘ plumbers, HVAC technicians, as well as apprentices/helpers have been certified in combustion and CO (carbon monoxide) safety.

Ken Scott (right) and Jeffery Peck participate in a typical in-house training session conducted by Masterworks Mechanical weekly.

‘But it is more than just that,’ Updike says. ‘We feel training is also an employee retention program. Our theory is that a technician who knows they are the most qualified, knowledgeable, and committed to our customers’ well-being exceeds anything any other contracting firm offers in our area. Our technicians develop a sense of pride and value for what they personally bring to each call. I believe this is what usually stops them from even considering offers from other shops.’

He says they conduct weekly training in-house on all aspects of the products and services Masterworks offers.

‘We average around 70-80% attendance by our techs and apprentices. Attendance is voluntary. Plus, we bring in outside training. We certify all field personnel in combustion analysis and CO. Installers and service techs are certified in system performance and residential and commercial air balancing.’

Training is not a Solitary Affair

The team at Masterworks depends on several sources for their training and certifications. Vic says first and foremost, they rely on NCI’s training programs.

‘I think it’s important how pivotal our involvement with NCI and its training programs have been for Masterworks,’ he says. ‘It is amazing to me how many members don’t realize the effect of the coaching and business training that comes with NCI. Many of the successful business decisions we’ve made have grown from seeds planted during our NCI interactions.

‘Masterworks and other HVAC companies are like college and high school football teams ‘ both are playing football but not on the same field.’

‘With the extreme focus Masterworks has on combustion and CO safety, I mistakenly assume that was NCI’s main contribution to our success,” Updike continues. “We truly could not have converted that to a sustainable business without the business side partnership from NCI. Masterworks’ continuing growth and sustainability are the direct result from the offerings provided by this organization.’

But training is not a solitary affair and Masterworks also works closely with wholesalers who Updike says have an ‘intense commitment to our training.’

Their three main distributor partners include Johnstone Supply in Grand Junction, Ferguson in Steamboat (yes that is a real city), and Winn Supply (also in Steamboat). These partners arrange to have manufacturer reps training on the various products that Masterworks carries and uses. Sometimes that training is at the Masterworks facility, other times it is at the distributor location.

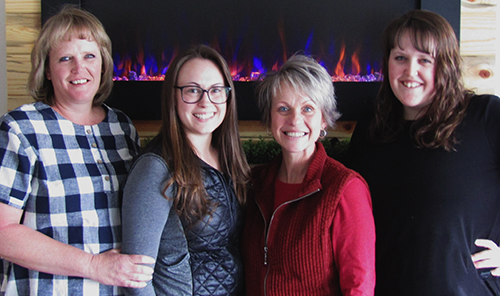

The Masterworks office crew includes (left to right) Amy Updike, Krystle Bohrer, Tkay Hall, and Taylor Peck.

‘This strengthens our market position in a ‘blue ocean‘ kind of way,’ Updike continues. ‘In other words, Masterworks and other HVAC companies are like college and high school football teams — both are playing football but not on the same field.’

‘The secret is that you cannot do this alone. If you want to be the best at what you do, you need help. So, look to partner with the best firms. And don’t forget about your fellow contractors. Networking is very important to our learning and training.’

Implementing Performance

According to Victor Updike, his focus on Performance-Based Contracting centers around combustion analysis. Over the last three years especially he says this focus has helped Masterworks grow because it enabled them to add new products and expand into new markets.

‘The first hurdle in implementing full out combustion analysis is committing yourself to the ‘why,’ you do what you do? Updike says. ‘That began with David DeRose. It really takes a lot of effort to answer that question.

“But once you do and place it into your culture, your techs won’t hesitate to answer unexpected customer questions or concerns. They also can make decisions based on testing and diagnosis. Our field team cannot do this if they don’t understand why Masterworks operates this way when none of the competition does.’

Click below for the next page:

Recent Comments