Measurement: The Secret Sauce

Updike points out that they built their combustion program using UEI analyzers. He says that as the technology advanced (as well as the training) they switched to Bacharach instruments.

‘One reason for this change: the test saving feature included in the tool saves into our dispatch program and lets us maintain historic data easier,’ he says.

In addition, Masterworks technicians use Testo tools for air conditioning and refrigeration testing.

‘The capabilities of such instruments allow us to perform service by measuring not guessing. To be honest, we’ve found through our implementation process that any requirement we put on our technicians that is cumbersome or time-consuming has a much lower success rate.

Jason Blackwell pulling inventory for a job.

“The latest tools and instruments contribute to the ease of conducting measurements and have enabled us to collect all the necessary data on each start-up and service call. That is really the secret sauce to our performance success.’

In addition, Masterworks removes the burden of tool purchasing by providing their techs with everything they need to be successful.

He points out that at first, the field service and installation crews live off the great feelings from life-saving success stories that happen on the job. He says because of combustion analysis, they can find and resolve CO issues before a serious negative event can happen.

‘CO saves happen fast and in a surprising amount,’ Updike adds.

‘Lastly,’ he says, ‘you will cause some unintended results. For example, a realtor hires you for a furnace inspection before a sale. With your commitment to combustion testing, you will inevitably condemn equipment — a headache for the realtor. A competitor most likely won’t identify these issues, so we may lose the job. We can overcome this through better communications ‘ using easy-to-understand verbiage. This is the ‘why’ of your commitment to performance. Having the ‘why’ locked down, forces/helps you keep your commitment.’

The benefits, according to Updike, are tremendous. Besides setting Masterworks apart in their marketplace, it also seems to have set them up as experts ‘ even with regards to product design. He shared that, with the commitment of his equipment distributor (David Rhodes from Grand Junction Johnstone Supply, who is also combustion certified by NCI), his team was brought into an equipment manufacturer’s factory to talk with product engineers and designers about problems Updike’s crews found in new equipment, based on their combustion analysis.

‘I believe that NCI training took this high-school-educated kid and placed him in the same room with engineers and university graduates, to explain theory and principles that were new to them. Corrections were made on the assembly line resulting from the meeting. It is still amazing to me.’

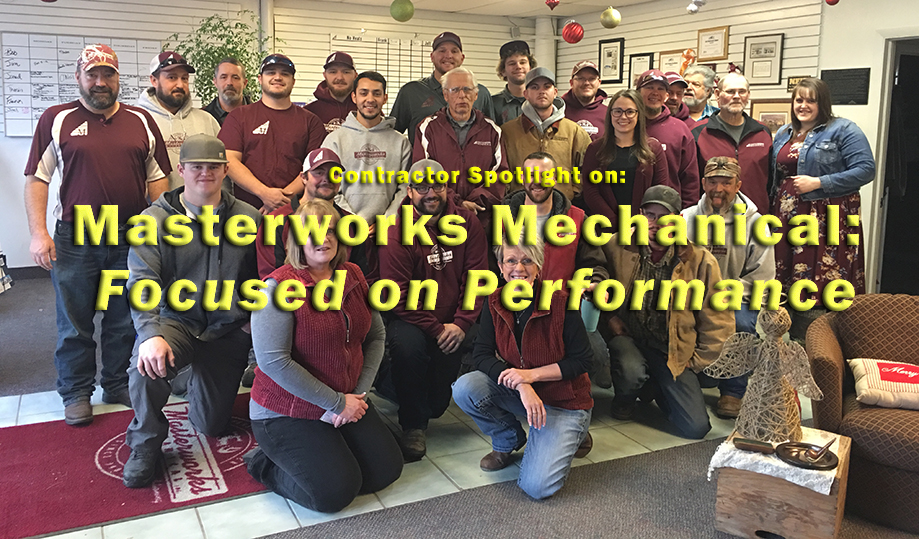

Masterworks? Performance Culture

Though he says implementation is an ongoing process, Victor Updike says it is well-established in the way they conduct business now. For example, he says they wrap the low end of air and system upgrades into every furnace replacement quote. He says it enables him to talk about the importance of maintenance to make sure that not only the equipment but the ductwork as well work to their design.

‘And I can back up what I’m saying,’ he continues. ‘How? Because we measure everything. Before and after every job. We have the numbers to show that what we did worked.’

The result: Masterworks offers products and services nobody can compete with.

Updike says the key to their successful delivery of the services and care of their customers is the team.

‘The fact is,’ he explains, ‘our team has an untrainable dedication to Masterworks’ image and our customers’ well-being. It comes from the culture, the family approach to management, and empowerment.

‘We believe this to be our primary focus,’ Updike adds.

‘We try to assure each co-worker feels they have control of their place in what we deliver. I feel each person here has the most dedication to what they do to contribute to Masterworks’ mission than can be found anywhere else. Basically, they operate like this company is their own. Amy and I are just the steering wheel.’

Click below for the next page:

Recent Comments