ABC’s Part 7, continued

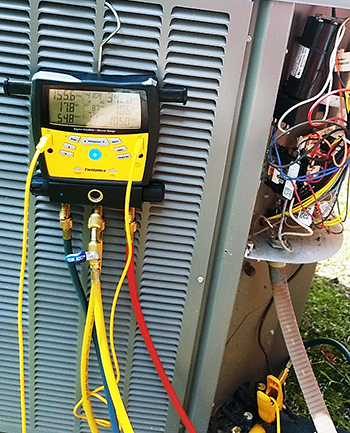

Digital Refrigerant Gauges: With today’s increasingly sophisticated higher efficiency air conditioners and heat pumps, analog gauges just don’t cut it any more.

If your techs own them, it’s not a bad idea to hang onto to them as they may come in handy in a pinch, but your field people’s go-to instruments should be digital.

There are many benefits to digital manifolds. One is you can use them on a spectrum of systems with different refrigerants, ranging from traditional R-22, 410A, 134A, and more.

There are many benefits to digital manifolds. One is you can use them on a spectrum of systems with different refrigerants, ranging from traditional R-22, 410A, 134A, and more.

Today’s manifolds include programs for 40 or more different refrigerants. They come in many configurations and degrees of technology. All of them automatically calculate Superheat and Subcooling, but some are more accurate than others.

Some digital manifolds are fully computerized, and can perform very sophisticated diagnostics. Many now include wireless technology and applications for mobile devices.

The key is getting the right tool for the person using it. It’s usually a good idea to get something with a few more features than you think you may need, but there is no need to buy the top of the line with all the bells and whistles ‘ especially when first starting out.

Technology is moving so fast that you may want to move up to something better in the next year or two that outperforms today’s top-of-the-line instruments.

Combustion Analyzer: A high-quality combustion analyzer can be used for CO safety checks, combustion diagnostics, and precision burner adjustments. Residential/light commercial combustion analyzers range in cost from $600 to $1,500, depending on quality and accessories.

An important feature to look for in a combustion analyzer is fast response to CO and oxygen level changes. When you look at the specs, check out the pump volume. The more volume it can pull, the faster the analyzer will respond to changes. At minimum it should pull at 400 cc/min. A better volume is 700 cc/min.

An important feature to look for in a combustion analyzer is fast response to CO and oxygen level changes. When you look at the specs, check out the pump volume. The more volume it can pull, the faster the analyzer will respond to changes. At minimum it should pull at 400 cc/min. A better volume is 700 cc/min.

A high-range CO sensor is also important ‘ the higher the range, the more likely it will quickly bounce back from a very high reading in a flue. Look for a minimum high range of 4,000 ppm. 8,000 ppm is better.

Another key feature is calibrated replacement sensors. These sensors make it possible to avoid sending the instrument back to the manufacturer to replace a sensor. This will save you both time and money.

A built-in draft gauge usually adds $100 or more to the price, and is rarely used. In most testing situations draft should be checked with a separate instrument. Other features to look for are data-logging and printing capabilities (to provide date-stamped documentation).

A built-in draft gauge usually adds $100 or more to the price, and is rarely used. In most testing situations draft should be checked with a separate instrument. Other features to look for are data-logging and printing capabilities (to provide date-stamped documentation).

Draft Gauge: Draft gauges are important instruments for troubleshooting combustion systems. While there are digital gauges available, an inexpensive, extremely durable Dwyer 460 Air Meter does the best job at a cost of less than $50.

Every service technician should carry one of these on their truck with their analyzer. Remember, blowing smoke up a ‘ue bonnet does not verify adequate draft or venting.

Airflow Capture Hood: A quality ‘ow hood costs between $2,500 and $3,000. There are so-called residential or low-‘ow hoods on the market for $1500 or less, but they typically lack repeatability and accuracy.

This is the one instrument you shouldn’t cut corners on. It will become your go-to instrument and you’ll need to trust your readings.

A good digital hood should be able to consistently and quickly measure from 30 to 2,000 CFM on both supply and return grilles with an accuracy of – 3%.

A good digital hood should be able to consistently and quickly measure from 30 to 2,000 CFM on both supply and return grilles with an accuracy of – 3%.

Hoods typically come with a 2 ft. X 2 ft. skirt (opening size). Different size skirts used mostly in commercial air balancing are typically available as accessories. Some hoods offer features like wireless communications and datalogging.

The key is to choose an instrument that best fits how your company will use it. For example, a residential salesperson might be better off with a simple hood he or she can use to quickly capture one or more airflows to show the customer where the biggest issues are.

Your balancing technician may benefit from a hood that captures readings easily and helps quickly navigate the balancing process.

If you’re buying your first hood, start with a good basic model, so you can figure out what features and benefits best suit your company and each individual that will be using it.

Recent Comments