Skills You Need to Rate Total HVAC System Performance

Now that you have a list of resources, you need to ensure your team has the essential skills. Before any testing begins, a certified technician must gather all the equipment and system information.

Much of the information should be on file, such as equipment nameplate data that includes model numbers, airflow capacity, and maximum rated TESP (Total External Static Pressure). Other information, such as fan speed settings and filter sizes, might not be accessible until the testing technician is on the job.

It takes a knowledgeable, well-trained technician to test and measure the system to obtain the correct information. The testing technician should be able to measure:

- Static pressure at the equipment

- Airflow from the equipment and system

- Temperature from the equipment and system.

Once the technician has these measurements, they must be able to interpret the readings to assure nothing is out of line or missed.

There are a lot of measurements recorded simultaneously, so it’s easy to miss something, test out of sequence, or measure in the wrong location. Some test results to interpret include:

- Assuring the equipment type and capacity are correct

- Using static pressure diagnostics to identify readings that don’t make sense or might be higher than expected

- Conducting airflow diagnostics at the equipment and system to assure the readings are in line with other

- system measurements

- Using temperature diagnostics at the equipment and system in case there is an issue with refrigerant charge or combustion on a gas furnace

- Identifying other factors affecting system performance, such as excessive attic temperatures or abnormal return temperatures on a new startup.

If all the measurements are in line and make sense, it’s time to input your readings and information into ComfortMaxx Verify. If something doesn’t line up or is off, you’ll need to investigate, diagnose, and correct these issues before you continue. They may affect the HVAC system rating.

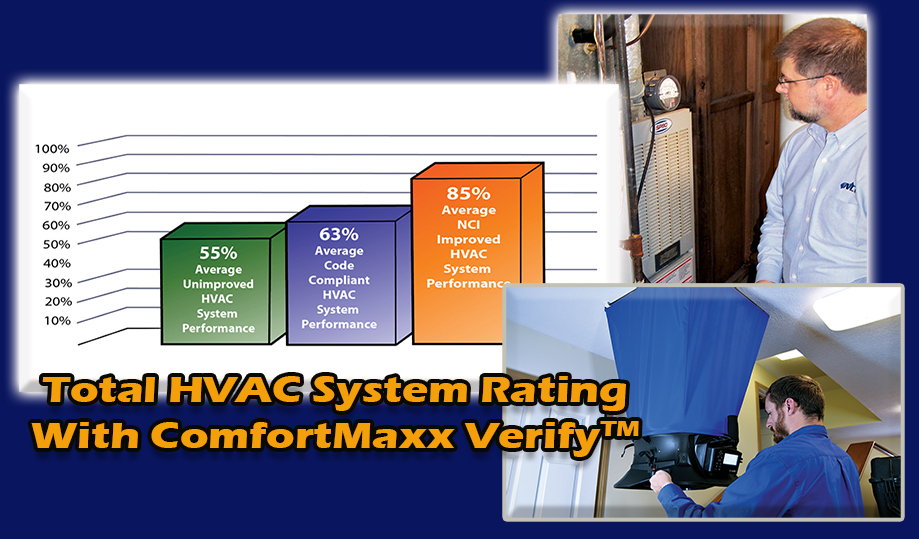

ComfortMaxx Verify™ is the HVAC System Rating Engine

As you input data into ComfortMaxx Verify, it does the rest. It is the engine that provides all the calculations to rate HVAC system performance. ComfortMaxx Verify collects:

- Customer information – a permanent record in the cloud of your customers’ HVAC system information

- Location information – matches equipment and systems to specific locations in a home with more than one HVAC system. You can rate each system for each location

- System information – keeps a record for past testing as a comparison to future measurements to assure the system remains operating in the best condition possible

- Test results and calculations – static pressure, airflow, temperature, and Btus are captured and compared to equipment and system specifications to create a final rating of the installed HVAC system independent of the HVAC equipment rating.

Click Below for the Next Page:

Recent Comments