One of the most significant challenges our industry faces is understanding the difference between HVAC equipment and the HVAC system. Many contractors and their customers believe the equipment and the system are the same. They assume a 95% furnace and 22 SEER condensing unit automatically perform at their rated efficiency once installed.

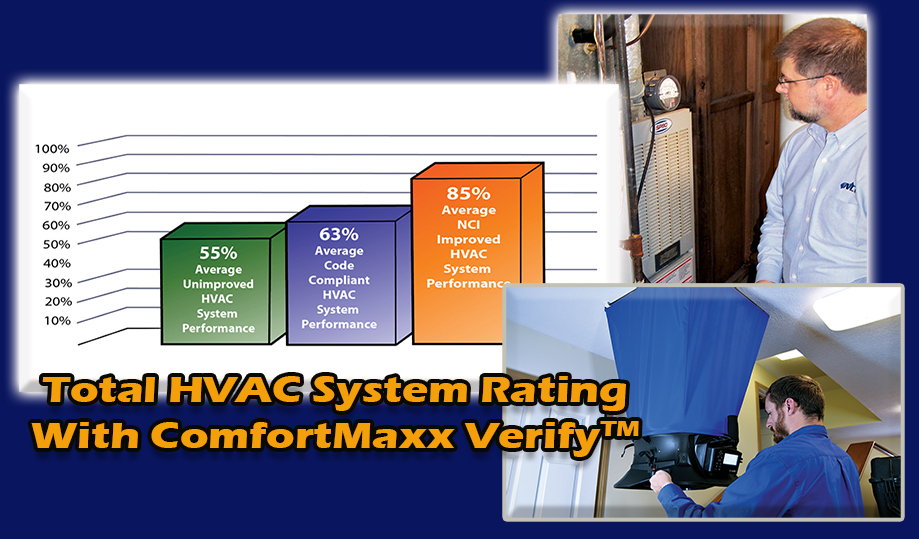

HVAC system rating and verification sheds new light on this assumption. System rating and verification reveal contractor craftsmanship and installation conditions’ influence on the installed HVAC system. Let’s look at what’s involved in an HVAC system rating and how ComfortMaxx Verify™ ties in.

The Importance of HVAC System Ratings

The HVAC industry is one of few specialized professions that designs and field assembles multiple mechanical components to create an HVAC system. This task is quite an undertaking since various people with different roles ensure everything works in unison.

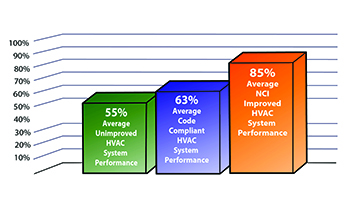

To deliver what you promise and what your customer pays for, you need a way to rate your installations. In its simplest form, an HVAC system rating looks at the total heating or cooling Btus the HVAC system delivers into the living space. Then you compare them to the amount of Btus the equipment produces under tested conditions.

A rating considers all the variables, from proper design to the installation conditions. It looks past the laboratory-rated efficiency of the HVAC equipment. An HVAC system that achieves a rating over 90% is doing an exceptional job. But in some locations, like attics, that result is hard to achieve.

HVAC system ratings provide an HVAC system assurance policy. It gives your customers the confidence that the equipment they purchased operates as intended. In addition, it gives you a way to set yourself apart from your competition, which only focuses on the yellow labels and equipment laboratory ratings.

Adding software, such as ComfortMaxx Verify™, provides third-party credibility so you can focus on results instead of assumptions. It is the craftsmanship litmus test that proves how well your HVAC systems perform.

Everyone in Your Company Determines the HVAC System Rating

It takes everyone in an HVAC company to achieve an acceptable HVAC system rating. There isn’t one person who holds all the responsibility or anyone who can become the scapegoat.

HVAC system ratings start with company owners and management. If they don’t decide it’s essential to assure their installed systems work as designed, the steps to rate the system will never happen.

Company leaders must instill system performance as a culture. No one else can do it. If they believe in the benefits and opportunities in rating system performance, they can share the vision with everyone. From there, the concept catches on throughout the company.

Click Below for the Next Page:

Recent Comments