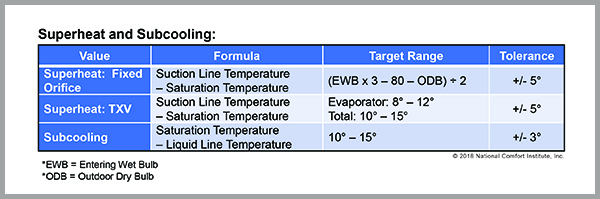

While typical subcooling will be between 10 to 15 degrees, you may find specific condensers and heat pumps that have lower values based on varying designs in condenser coils.

Low subcooling can indicate a low refrigerant charge or a metering device that is overfeeding. High subcooling can indicate the system is overcharged, has non-condensable liquid in the system, a liquid line restriction, TXV bulb failure, or an inefficient compressor.

In one utility program, contractors submitted more than 700 ComfortMaxx Verify’ tests for utility rebates. These were full test-ins of commercial systems where contractors input measured static pressure, airflow, and temperatures into the ComfortMaxx? (ncilink.com/CMaxx) online software.

The software calculated delivered Btu’s and Cooling System Efficiency Scores (CSES). Looking over a test sample of 178 systems, we found 88% of them had low airflow.

Diagnostics Time

With such a prevalent issue of low airflow, what do you suppose the impact would be on that equipment’s refrigerant cycle? Could you misdiagnose the problem on a service call?

When airflow decreases, the available heat entering the indoor coil decreases as well. Looking at the structure of a Pressure-Temperature chart, you’ll see that pressure and temperature increase together. So, if you have less heat, your evaporator pressure will be lower.

As the refrigerant leaves the evaporator, any heat it has gained beyond the vaporization point is evaporator superheat. Any additional heat gained traveling thru the suction line is total superheat. Total superheat is what most technicians use for diagnosing the system. With lower-than-expected pressures leaving the evaporator due to low airflow, the compressor may not elevate the pressure and temperature high enough to reject heat to the outdoor air effectively.

Callback Reduction

One reason refrigerant charge adjustment does not achieve meaningful energy or efficiency gains is that techs often mistake low airflow as a result of a low refrigerant charge. They have often misdiagnosed this as a result of the suction and discharge pressures both seeming low. The technician then adds refrigerant charge. They then find that head pressure and compressor energy consumption increase but do not gain the correct enthalpy change or Energy Efficiency Ratio (EER).

So if you’re interested in fewer callbacks and discovering more sales opportunities, take the time to gather all the facts. Don’t assume the first problem you find is the only problem. Remember, subcooling and superheat are only two pieces of the puzzle. Therefore, the more clues you can piece together, the greater the likelihood you will get the results you want and that your customers need.

Justin Bright is a 24-year HVAC veteran who serves as a field coach and instructor for National Comfort Institute (NCI). He left the industry for a time and served as a Sonar technician aboard submarines. Today he is based in NCI’s California office and can be reached at ncilink.com/ContactMe.

Recent Comments