I went to the Maryland State Department of Labor in 2010 to request starting my own apprenticeship program. I had to do all kinds of paperwork, create a syllabus and gather training materials, then submit everything for approval.

They approved it, and now I have my own in-house state-approved apprenticeship training center.

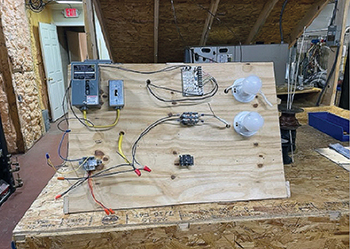

Minnicks Training Center has several rooms – one holds up to 10 people, the other holds 35 to 40 people. A separate room contains all the different equipment, control boards, and everything else necessary for us to do hands-on training.

We also do home performance testing and training; we have a BPI-certified test house, and I am a BPI Proctor with all their certifications to do their training within our company.

I make training our own, and all my employees go through those classes to get certified. Because I am a BPI proctor, we even train other HVAC technicians for BPI certification from up and down the East Coast.

Fall Is a Time to Review and Plan

As summer winds down and fall begins, I have a bit more time to sit back and take a hard look at the business. This is when I start figuring out our current strengths and weaknesses, where future revenue streams will come from, and how to ensure we are set up to grab those streams.

I look at our numbers monthly, even during the busy seasons. Knowing our numbers helps me keep my finger on the pulse and see what changes we need to keep our team working and revenue rolling in.

electrical wiring.

Fall slowdowns allow me to sit down and discuss those numbers in more detail. This is also when we can implement creative new plans or service offerings. Fall is when we test drive anything new.

For instance, this year, I signed up for The New Flat Rate (TNFR) pricing system in May.

We got it all set up and launched it mid-Summer. We did some training through June because TNFR requires you to attend three virtual classes, which was great. After all, we don’t have time to go to Georgia during the summer.

Then we had to get everyone on board and understand what it is, why we are using it, and so on.

During the fall, we will discuss the problems with this new software and work out any bugs. That way, we are up and fully running with it.

This launch was unusual in that we launched during summer. I did this because flat rate pricing makes things simpler for our technicians. Plus, it gives homeowners choices – something I’ve been trying to build with good, better, best scenarios.

Recharging through Remote Monitoring

We offer a standard maintenance agreement at Minnicks, but our main agreement is for remote maintenance monitoring. Remote maintenance is where we install a device on the customer’s HVAC system that monitors it 24/7. This program helps our field service and installation teams recharge because it can run through maintenance routines remotely, saving them road time.

Another advantage of offering these agreements is they reduce fuel costs on our vehicles, especially with today’s high gas prices.

It works like this: we go into our online portal and ask it to run cooling or fall maintenance routines. It will turn customers’ systems on and run through all the maintenance checks just like a tech would do.

The device then lets the homeowner and us know if there are any issues or concerns. Technicians only visit the locations if the monitoring system detects a problem or other big concerns.

Furthermore, remote maintenance monitoring helps us precisely schedule Spring air conditioning tests. Most air conditioning manufacturers don’t want contractors to run the cooling unless it’s 55°F or warmer.

Click Below for the Next Page

Recent Comments