I’ve also seen research indicating that ductless heat pumps do not control humidity as well as ducted heat pumps. I’m not sure why this is, but I guess that ductless units tend to keep airflow higher relative to capacity than their ducted cousins. Why?

Because they must distribute the air through the space from a single air handler head rather than through multiple supply registers.

Regardless, it may be best to think twice about using ductless systems where humidity is a concern.

Installation, Commissioning, and Controls

Proper equipment installation using adequately sized, well-insulated ducts that don’t leak is required to operate any equipment properly. Inverter systems are no different.

Another universal requirement is correctly setting airflow and refrigerant charges for proper system operation. When setting airflow, a lower range of 300 to 350 cfm/ton helps lower the equipment’s Sensible Heat Ratio (SHR) and is helpful in humid climates.

Fine-tune the refrigerant charge after setting this lower airflow.

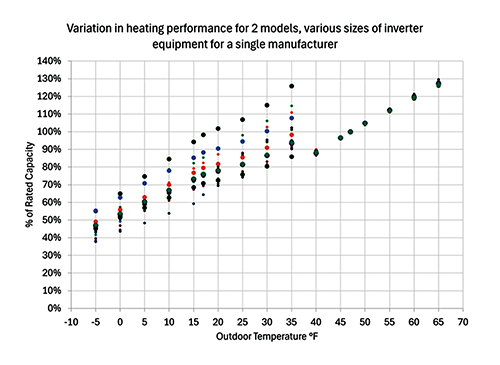

perform quite differently. Get the specific data for the unit(s) you are considering!

Regarding controls, most inverter systems use communicating thermostats that have some built-in functionality that is helpful for moisture management. There is often a “dry mode” that keeps airflow lower relative to capacity throughout the operating range.

Dry mode helps maximize latent capacity at the expense of some total capacity as the equipment modulates down. Confusingly, some manufacturers call this the “humid mode.”

The lesson: you must know the equipment you sell!

Along with dry or humid modes, some thermostats allow you to set an over-cooling allowance when indoor humidity is high. I recommend limiting over-cooling to 1°F or 2°F below setpoint, which could lead to a cold and clammy feeling in the room.

It Comes Down to Sizing, Selection, and Setup

As you can see, a lot goes into thinking through sizing, selecting equipment, and setting it up correctly (The Three “S’s”) to provide customers with first-rate moisture management even with today’s excellent and smart inverter heat pumps. During your next few heat pump jobs, take your time and think through the Three S’s, and you’ll begin to understand what you need to do in your area to make systems work as well as they can.

You’ll soon discover standard practices you can apply to every job that make your heat pumps work much better than competitors simply doing like-for-like replacements.

Maybe you’ll only install cold-climate heat pumps. Perhaps you’ll always install a standalone dehumidifier. Maybe you’ll avoid a brand whose performance doesn’t match well with the homes you tend to work on or your climate.

Feel free to comment and share any best practices you’ve found in your area. I would love to hear how others are approaching moisture management with heat pumps or even just heat pump design in general.

Ben Lipscomb, P.E. has more than 16 years of experience in the HVAC industry, including laboratory and field research, Design/Build contracting, and utility energy efficiency program design. He is National Comfort Institute’s director of engineering and utility services. You can contact him at ncilink.com/ContactMe with any questions.

Recent Comments