Interpret Your Readings

If we choose a coil rated at .4′, that will use 80% of the fan’s available pressure. There is still one more option; by increasing to a 3 ?-ton coil, we could reduce the pressure drop to .17,’ allowing for degradation due to buildup on the coil.

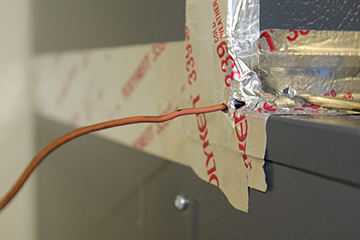

If a previously installed coil is showing signs of excessive pressure drop, cleaning the coil will lower the pressure drop in most cases. Before spending time cleaning the coil, make sure to verify that the coil is installed correctly and is appropriately sized for the system airflow.

Use fan tables from the manufacturer’s installation instructions or the National Comfort Institute Airmaxx app to verify blower airflow. Compare the measured static pressure at the operating airflow to the manufacturer’s rated static pressure drop.

You may need to use Fan Law Two (ncilink.com/FanLaws) for when you encounter airflow tables that do not list your design airflow.

If you see that the coil has a lower listed pressure drop than the pressure measured, cleaning the coil is warranted. Along with cleaning the coil, you should minimize the source creating buildup on the coil.

Look for leaks in the duct system which bypasses the filter. Consider adding weather stripping at the filter to provide a better seal.

Coil Cleaning

Coil cleaning techniques vary from company to company. Some companies have policies that require using water for cleaning. Water will rinse the coil clean while minimizing damage to the coils that can happen if you use a corrosive chemical.

In reality, when cleaning a coil in place or when the coil has been exposed to cooking oils on its surface, chemicals may be necessary.

After cleaning the evaporator, restore airflow to as close to design airflow as possible. Install a static pressure port sticker and list the date, coil pressure drop, and airflow on it. This provides a reference for future visits.

On each service or planned maintenance visit, you can track the increase in static pressure. Then you can create a custom coil cleaning schedule that reflects the individual coil’s installation quality, the customer’s level of operation, as well as the environmental impact of buildup on the coil.

Be sure you’re not limiting your troubleshooting to the evaporator alone. Remember that the coil pressure drop is only one component of a system’s pressure budget.

Click Below for Next Page:

Recent Comments