Excessive pressure drop in other components may reduce overall system airflow, making the coil appear to be within budget. Restoring airflow by correcting other components may increase airflow through the coil, which would increase the pressure drop across the coil.

A Brief Case Study

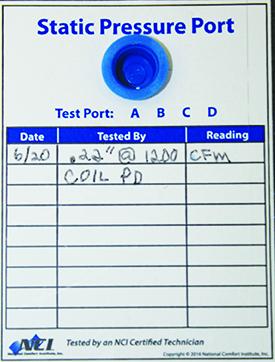

Recently I was on a job site with a contractor. He had replaced an evaporator and was having issues with the refrigerant cycle. The system evaporator had a 40-degree temperature drop and a pressure drop of .8?. The coil was exceeding the pressure budget of 0.2?.

We used a boroscope to perform a visual inspection through our static pressure port and found several issues. The TXV sensing bulb had been mounted upside down with its tubing facing down. The insulation had fallen off the inside of the casing and had frozen to the coil. Plus there was excessive coil bypass at the drain pan through a three-inch gap.

After making corrections to the evaporator, the pressure drop decreased to .41?. This was a perfect example of what happens if you pick up a coil without looking at its engineering data. The excessive coil pressure drop, along with the overly restrictive electronic air cleaner, left this system only able to deliver 80% of its airflow.

If the customer had been willing to wait for a better coil option to be ordered, the pressure drop would have been lower. Originally the contractor had offered a broader scope of work, which would have addressed other performance issues, but the customer had a limited budget.

Provide Customers Choices Based on Data

In many cases, we are not able to make all the corrections we want. But through testing and collecting data, we can provide customers with the information they need to make an informed decision and have reasonable expectations of the results within their budget.

When a customer asks me why I need to perform a static pressure test when other contractors don’t, my answer is to provide them with enough information to understand the problem, how severe it is, and what results to expect from the options available.

So, tool up, take the time to test systems and discuss your solutions with customers. It only takes a few minutes of practice on each job to master static pressure testing and turn tests into sales.

Justin Bright is a field coach and instructor for National Comfort Institute (NCI). He began his HVAC career working for a large production housing company in 1997. Bright has worked as a Sheetmetal fabricator and system installer, plus he has military experience and attended trade school for both plumbing and HVAC. He worked for several years designing, installing, and servicing HVAC and plumbing systems for residential and commercial (up to 400-ton chillers) systems. Today he trains students in all NCI disciplines and is an instructor for NCI’s Southern California Workforce Education & Training program. You can contact him at ncilink.com/ContactMe.

Recent Comments