The final steps are typically the sole responsibility of the TAB contractor and overlap with the mechanical contractor.

- Step Eight: Compare Allowable Leakage to Actual Leakage

- Step Nine: Pass or Fail the section of Duct

- Step Ten: Complete Final Report.

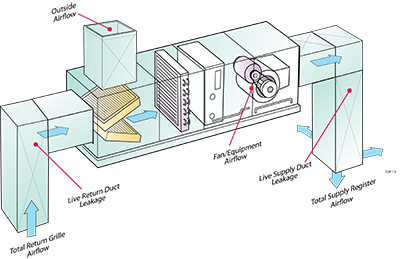

Not All Leakage is Obvious

Not all leakage is evident if the system fails and needs to be resealed. Sometimes it’s minimal, but it spreads across a wide area and can be significant. For example, two CFM is virtually undetectable.

However, two CFM at 100 locations is ½ ton of cooling capacity lost.

Often, contractors look for gaping holes or obvious gaps when the reality is much more complicated and invisible to the naked eye.

Also, as a TAB professional, when explaining to a mechanical contractor that their system failed the Duct Air Leakage Test, you can present all the statistics and numbers and explain the physics and equipment. Still, they only hear one thing: “You didn’t do your job!”

Regardless of the statistics and physics, the TAB professional must present this information as politely and professionally as possible and be aware of what the contractor hears and thinks.

After the duct is resealed, the sealant needs time to set. Twenty-four hours is a typical time frame. Testing too soon after resealing will blow out the sealant and result in a second failure.

Invest in Proper Leakage Testing Tools and Instruments

Commercial Duct Air Leakage Testing requires very specialized and durable equipment. There are only a few manufacturers of these devices, most of whom are based in the United States. The oldest and best-known is the McGill Leak Detective.

Oriflow currently makes three models – the Cobra, Panther, and Rhino – all capable of testing up to 10 in. The Oriflow Rhino model can test up to 57,000 square feet of duct at four inches of water column.

TSI/Alnor produces the Positive And Negative Duct Accreditation System or PANDA. As the name states, the TSI/ALNOR PANDA, or PAN231, can test under positive or negative pressure.

Regardless of the brand, equipping yourself to conduct commercial DALT requires a significant investment. However, that is the cost of doing the job correctly and why everyone isn’t doing it.

Unfortunately, there is little training available on how to conduct DALT. It is typically a skill set handed down from one generation of technicians to the next.

Many SMACNA training centers offer courses in HVAC Air Duct Leakage. SMACNA even provides online training for its members. Beyond SMACNA, be careful when researching training, as most courses target residential testing, which is an entirely different animal.

In closing, Commercial Duct Air Leakage Testing is critical to the mechanical construction process. As multiple municipalities and states move towards electrification, the cost of Air Leakage in commercial systems will skyrocket.

There will be more demand than there are contractors trained and equipped to perform it. The consequences will be more severe as energy grids become more burdened and stretched.

Scott Fielder is the Director of Field Operations for Evergreen Telemetry, a Phoenix-based TAB equipment manufacturer. Scott has over 23 years in the TAB industry, including 15 years working in the Texas field and seven years providing TAB training and training development. You can reach him at ncilink.com/ContactMe.

Recent Comments