National Comfort Institute (NCI) training covers as many combustion problems as possible on equipment in the field. NCI created diagnostic charts for many different types of equipment. However, there will always be situations in the field that don’t conform to these charts.

When the measurements we get don’t fall into charted areas, what should we do? It is important to note that we are talking about measurements outside NCI and possibly industry standards.

The following problem arises in this area.

The Scenario

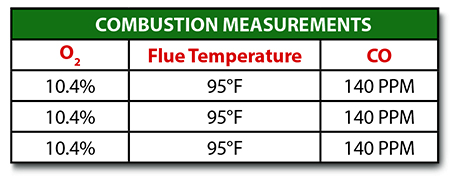

An HVAC contractor finds the following after servicing a condensing furnace and doing a combustion test on a two-pipe installation – The combustion test measurements are as shown in Chart 1:

The NCI Combustion charts show that:

- O2 should be between 6% to 9%

- Flue temperature between 100 and 140°F

- CO should be less than 100 ppm.

The O2 and CO should be stable, as show above.

The O2 and flue temperature indicate an underfired condition. The NCI diagnostic sheets show that the CO reading cannot specifically identify an underfired problem. This is because underfiring can cause CO to be high, over 100 ppm or 0 ppm, or anywhere in between. So the contractor called me for help.

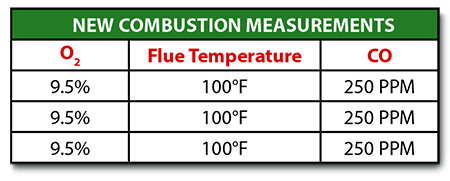

Because the CO is above 100 ppm in this case, one way to determine if underfiring is causing the situation is to raise the gas pressure slightly. I asked the contractors to do that, and the new combustion readings are shown in Chart 2:

These results show that it wasn’t underfiring, causing increased CO. The CO is over 100 ppm and stable. That only leaves a DAM problem – Dirt/Alignment/Mechanical.

What is the DAM Problem?

The contractor had just cleaned the furnace. He removed the burners, cleaned them, and carefully replaced them. But is it possible one of them might be off just a little?

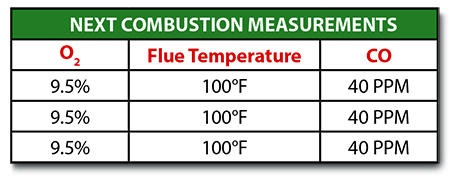

In this scenario, the furnace had a sealed burner box, so the cover needed to be removed to see the burners and flames. I asked the contractor to remove the cover and do a visual inspection. What happened next might be considered weird. Here are his next set of measurements with the cover off. The results are in Chart 3:

The O2 reading remained the same. CO dropped to an acceptable range and was stable. No change in the O2 reading indicates the amount of air entering the furnace stayed the same and eliminates combustion air as the problem.

But wait! The NCI Diagnostic Chart already eliminates combustion air as a problem on a condensing furnace. How can removing the burner box door fix a DAM problem?

Click Below for the Next Page:

One of the first things you learn in the Combustion/CO training is orifices are typically 10% to 15% undersized, which makes gas pressure a token measurement with no real value.

Although most manufactures still list CO2 in their manuals, CO2 can vary up to 10%. We are always making 99.99% of the CO2 if the CO is less than 100 ppm. O2 tells us how much it is diluted and is more accurate.

You are correct in that I should have mentioned if there was any change in the readings with the blower on or off. No change – first thing we watch. Also, if the gas pressure changed with the burner box open, the combustion analyzer would have shown that.

Unlike air conditioning, the blower speed cannot be set correctly until combustion is corrected. Sometimes when airflow is too low you do have to make some adjustments at the same time.

If you are depending on the manufacturer’s blower specs and Delta T, then none of your blowers are set correctly.If you do the math you will see that they don’t make sense.

— Design firing rate does not affect combustion readings.

— Gas pressure verifies nothing.

— Delta T is the same on all furnaces if the blower speed is correct.

Based on the information provided on this article, there is not enough data to properly diagnose the problem; such us:

— Design firing rate vs actual firing rate.

— Design manifold pressure vs actual manifold pressure.

— Design Temperature rise vs actual temperature rise.

Does the manifold pressure change when the burner cover is removed? (Let’s not forget that the gas valve will regulate the manifold pressure based on the burner compartment pressure).

On the combustion side I would like to see the CO, CO2 and O2% levels simultaneously.

Does the combustion data change when the blower turns ON?

It’s like trying to diagnose a refrigeration problem based on refrigerant pressures and Delta-T alone,

In general, it looks like the unit is under firing, hence the high level of oxygen and low stack temperature.

I Believe that beyond economics, we should figure out any problem that we run into, because at times we may lose a day or two but in the long run we gain more knowledge and confidence, and we should charge the equipment owner that time anyway.

Also, the feeling that there’s no problem you cannot solve (within reason) is priceless.

Very informative article Jim. Thank you for the detailed knowledge!