This Can Change Everything

The future is technicians who can do things they never could before – like predicting the scope of work.

Think about this: once you have a TrueFlow report, and by using some additional math, you can then predict what would happen by adjusting airflow.

Could we not do the same thing with changeouts? In other words, if you have a TrueFlow report on an existing system that includes the static pressure and airflow measurements, we essentially KNOW what the ductwork can handle no matter what you throw at it.With that much data, taking it to another level is not far-fetched.

You’ll know how things respond to airflow. If you move x-amount of air at a specific pressure drop, you can predict what will happen to that static pressure if we increase airflow. Why is that

important?

Heat Pumps and Other Tech

Our industry is currently going through a heat pump revolution that’s driving us towards electrification. Many gas-fired furnaces will likely be replaced with electric heat pumps. There will also be many furnaces that will remain installed acting as a vital component in a dual-fuel system.

The airflow required to move the same capacity to these areas in predominantly heating climates will potentially increase. It becomes a huge decision about whether you can keep the exiting ductwork in the house or if upgrades are necessary. You have to consider whether a furnace to heat pump retrofit will really work.

Many times that’s a ductwork question. If you have static pressure and you don’t have an airflow measurement reading, you don’t have enough information to make an accurate decision. For example, if the system is dirty at all, you won’t have airflow, and your static pressures will look great.

But if you have static pressures and airflow, you have all the information you need to start predictive measuring or forecasting.

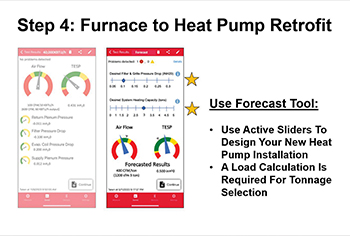

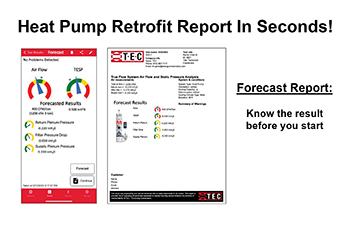

Soon, the next release update of the TrueFlow app will enable you to take airflow measurements and then push a button to forecast results of increasing or decreasing airflow, while also providing guidance on the type of equipment you select.

This type of software helps to create a scope of work and ensure you don’t inherit or create a bad duct system. It enables you to forecast and simulate what could happen if the changes to the duct system aren’t made. Plus, it could predict whether the new equipment airflow delivery will work properly or not.

Forecasting and Simulating will be a Game Changer

The beauty of this is that it’s not you saying it. This automated third-party report has credibility and provides the customer with information they can use to decide.

Click below for the Next Page:

Recent Comments