At R.E. Michel, as we interact with our HVAC contractor customers, we hear a common request: “What training can you provide?” This request is true throughout all our markets, coast to coast.

Professional contractors know that a well-trained service and installation team will result in fewer callbacks, lower warranty rates, and a satisfied consumer. These contractors invest their time in quality training, whether it comes through the factory, rep agency, contractor best-practice group, or their distributor. Contractors have told me throughout my career, “We work from word-of-mouth referrals.” Therefore, the consumer experience is vital to their success.

Director of Sales,

R.E. Michel Company

The pursuit of providing a great consumer experience leads many contractors to invest more in training their entire staff. Many contractors eliminate unnecessary stock rooms in favor of building training rooms and live-fire equipment labs.

Some invest in their own full-time training staff to provide customer service, sales, and technical support. Furthermore, many contractors join a best practice group to expand their reach for top-notch training.

Training Must Keep Up with Market Changes

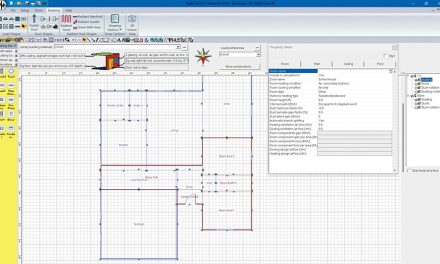

System Performance training session

at R.E. Michel recently.

This increased interest in training will continue for many years as our industry evolves. For example, there is the energy efficiency evolution. We currently have 13 and 14 SEER 410A equipment and SEER2 410A equipment in the market, and soon, we will have SEER2 A2L equipment as well. Understanding the differences and benefits of these offerings will be a challenge for all contractors to explain to their consumers.

The elephant in every job is the ductwork; is it sufficient for the equipment to operate as designed and deliver the comfort and efficiency as promised? Top contractors are invested in testing and measuring airflow performance in the ductwork.

The old adage, what gets measured gets done, applies to the duct system in every home. If you aren’t testing and measuring airflow, you risk the operation and lifespan of new equipment and consumer comfort. These contractors understand that the equipment is destined to under-perform if they don’t adequately size ductwork.

Airflow testing has become a standard for top contractors as they realize the direct correlation between good ductwork and a satisfied and comfortable customer.

Technical Team Recruitment Requires Training

As we move into three vastly different models of unitary equipment (SEER, SEER2, & SEER2 A2L) in the market and a necessary influx of youth into the trades (due to the ‘Great Retirement’), training will continue to be of utmost importance for our industry. Plus, we will see another refrigerant change at the tail end of this decade as we move forward from ‘mildly flammable’ A2L into ‘flammable’ A3 refrigerants.

Click Below for the Next page:

Recent Comments