Instrument Mistake 4: Using Thermal Hot Wire Anemometer for Traverse Without Accounting for Negative Readings

On another occasion, I was out with one of our veteran technicians who was having trouble finding a straight run of duct for a traverse. He drilled holes in the best location possible and gathered his readings using a thermal hot wire.

Knowing there would be negative readings, I asked him how he would account for those in his final measurement. He said there were no negative readings, and I introduced him to instrument mistake #4.

He was correct that his instrument doesn’t show negative readings. But that doesn’t mean there are no negative readings. The hot wire anemometer does not measure directionally. The numbers displayed, whether positive or negative, are displayed and averaged as positive. This will calculate a higher cfm than what your fan is actually moving.

The hot wire anemometer is another instrument used to perform a traverse. The probe expands and retracts to fit in a small carrying case, which is ideal to travel with. However, it is best to avoid using this unless you have a measurement location in a straight run of duct that is 7.5 duct diameters downstream and three duct diameters upstream from turns or transitions.

Instrument Mistake 5: Coil Face Velocity Measurements vs Traverse Airflow

Sometimes there just isn’t a way to take a duct traverse, but you still need to determine total airflow on an air handling unit. What do you do?

I was onsite at a manufacturing plant in Dallas with several units where a duct traverse location was not available. I instructed my trainee to take a velocity measurement at the coil inlet inside the unit to determine the total cfm. We discovered that airflow across the coil face was consistently 16% higher than the air-handling units we traversed.

We did not know if this was a project-specific issue or something common to all units. So, we compared coil face and traverse readings on a variety of projects with a wide range of units.

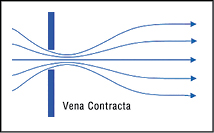

This is where we discovered instrument mistake #5: coil face velocity measurements read 16% higher than the traversed airflow. I believe the reason for this is Vena Contracta (ncilink.com/VenaContracta), an effect that causes airflow to speed up right before the area reduces.

Here’s how this works: Air velocity speeds up just as it enters the fins of the coil (the point of maximum velocity at the smallest area). By reducing the area abruptly, the velocity grid picks up a higher velocity in fpm and thus gives higher velocity measurements.

After looking at months of data, I discovered the 16% higher readings we saw at the manufacturing plant were the same across nearly all our projects. The best way to correct for this is to multiply your results by the remaining 84%. That will give you readings that are closer if you were able to traverse.

A word of caution: if your velocity falls below 300 fpm, or your measurement is taken on the leaving side of a coil, don’t use the 84% multiplier. The vena contracta effect is no longer a factor, and your readings without the multiplier should be accurate.

Brian Sharkey is the chief training officer for Airadigm Solutions, headquartered in Auburn, NH. His primary focus is on the technical on-boarding and development of Airadigm Solutions? TAB Technicians nationwide. He has worked in the field of Test and Balance and Commissioning for more than 25 years. Sharkey is NEBB Certified, LEED Certified, and NBC certified.

Recent Comments