Mel Johnson, vice president of utility programs for National Comfort Institute, Inc.

Lack of System Performance Awareness

Most consumers have minimal awareness and understanding of their heating, ventilation, and air conditioning (HVAC) systems. They typically regard the HVAC system as a simple appliance that is only noticed under the following situations:

- When it operates noisily

- It fails to deliver comfort

- If they see an upward deviation in their utility bill.

The fact is, most HVAC systems — whether noticed or unnoticed — are not achieving the manufacturers’ designed performance specifications. This performance variance goes undetected when temperatures are moderate and maximum cooling or heating is not in demand.

When an HVAC system operates in a degraded state, consumers have no idea it is running at a lower efficiency. They also don’t know they are not receiving the full capacity and efficiency of their systems. Unfortunately, many only realize something is wrong only when they:

- Receive an abnormally high utility bill

- Experience discomfort during the hottest or coldest parts of the year

- Are forced to make an emergency repair call for a premature component failure.

Most consumers want to get the most out of their systems for the least amount of cost.

A Multi-Sided Issue

HVAC system performance is not perceivable without measurement. Measurement allows a qualified contractor to better communicate to consumers with fact-based information about their system. This educates and equips them to make informed purchase decisions. Most consumers value this approach as it provides an opportunity to solve concerns with safety, comfort, and efficiency.

The reality, however, is that most HVAC contractors do not take an approach based on system performance measurement and improvement. Instead, they try to sell new equipment and service agreements. Or they only apply temporary fixes to help the system limp along until the next inevitable emergency call.

Opportunities to address underlying issues, for those contractors not performance-based, typically arise only when a consumer faces a system failure. That is when they must make a decision between repairing, replacing, or upgrading the equipment and system. Many utility programs rely primarily on this opportunity to offer high efficiency equipment replacements.

This replace-on-burnout (ROB) model limits the utility’s and customer’s success. It heavily relies on distributors having high-efficiency equipment in stock. It also relies on consumers typically being willing to spend the extra money to address hidden issues in the duct system. The result leads to the same performance degradation on the new equipment that caused premature failure of the old equipment. So, the cycle continues.

‘HVAC Systems Represent the Highest End-Use Cost

Consumers are not being informed about the impact of degraded performance on their comfort and energy costs. Degraded performance is a symptom of hidden issues that cause uncomfortable conditions, poor indoor air quality, and low efficiency. These hidden issues also result in unexpected system breakdowns and shortened equipment life.

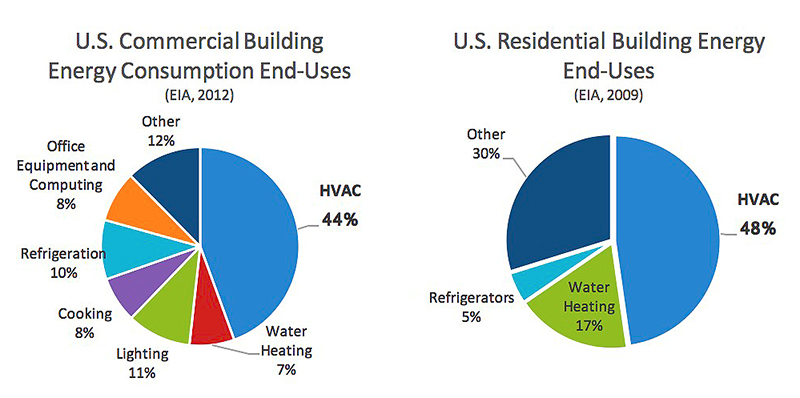

According to the U.S. Energy Information Administration, HVAC accounts for 44% of commercial building energy consumption, and 48 percent of residential energy consumption. More detailed regional load shape analysis shows that HVAC also comprises the largest component of both summer and winter peak demand, with its’ contribution typically exceeding one third of a building’s peak load.

Data source: https://www.eia.gov/

Data source: http://loadshape.epri.com/enduse

What these metrics mean for customers is that HVAC is their number-one energy cost, particularly during times of year when they have the highest utility bills. Utilities have a vested interest in flattening load shapes to avoid building new power plants and increase asset use for existing plants.

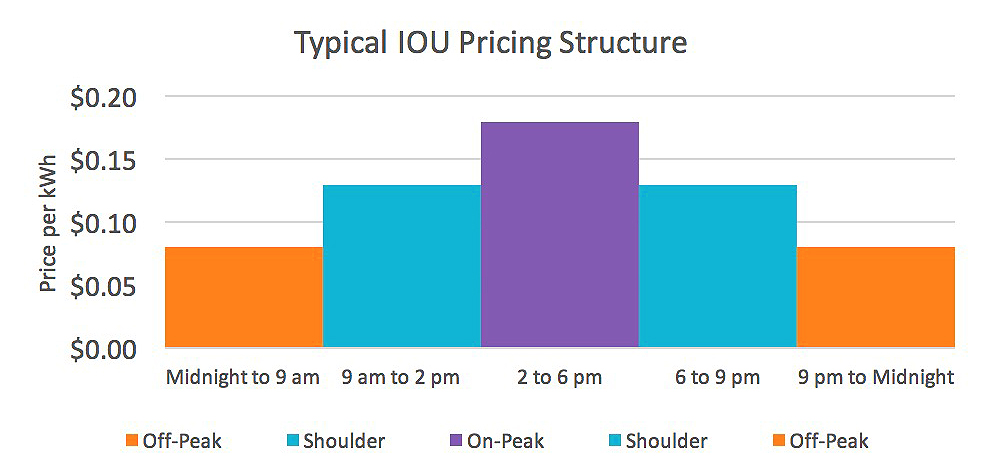

Smart meters allow utilities to send a pricing signal to attempt to get customers to reduce their electric usage during times of high demand. Strategies include peak demand charges, time-of-use pricing, and critical peak-period pricing. These strategies all attempt to match the pricing structure to the load shape, charging more money during times when the most energy is being used.

Each of these strategies share a common shortcoming. Customers cannot curb their demand if they don’t understand what is causing high energy use during peak periods.

Measured HVAC System Performance

To identify what causes high HVAC energy use, NCI captured and recorded field performance data for a sample of 155 commercial and residential HVAC systems around the country. This work revealed that the average system only delivers 43 percent of the equipment’s rated capacity to the occupied space.

HVAC systems performing this poorly result in extended equipment run time, increased energy use, and uncomfortable buildings, especially during the hottest and coldest parts of the year. The good news is that performance can be improved significantly. Renovation work on the same 155 systems increased system delivered capacity to 83%, an improvement of 93%!

|

National Comfort Institute, Inc. |

||

| Median Values |

Equipment Delivered % of Rated Btu/h |

System Delivered % of Rated Btu/h |

| Test In | 69% | 43% |

| Test Out | 93% | 83% |

| % Improvement | 35% | 93% |

By measuring performance on these 155 existing systems, contractors were able to show customers why their systems were not performing well and costing more than they should. For the first time, contractors were equipped to provide customers renovation work targeted at system improvement. They then verified the success of that work using the same measurement methodology they started with.

This end-to-end performance-based approach gives customers confidence that they are making the right decisions throughout the entire process, and seeing immediate reductions in their utility bills and improvements in comfort.

NCI Intervenes in California’s HVAC Strategies

On Sept. 18, 2008, the California Public Utilities Commission (CPUC) adopted California’s first Long-Term Energy Efficiency Strategic Plan (Strategic Plan) which included ‘Big Bold Goals’ for HVAC[1]. These goals were then taken one step further via an HVAC Action Plan to serve as a road map to transform the market.

As a result, California Investor Owned Utilities (IOUs) were required to adopt the HVAC Action plan and Strategic Plan strategies, and to take steps to incorporate stakeholder input into their energy efficiency program planning and implementation statewide.

In late 2010, the HVAC Industry was invited by the California Investor Owned Utilities (IOU’s) to provide professional services in support of an HVAC Action Plan and Strategic Plan strategies, and provide a focused performance-based HVAC workforce education and training (WE&T) effort under the umbrella of the 2009-2017 Residential & Commercial HVAC Programs.

A year later, additional professional services expanded the industry focus on promotion, delivery, measurement, and verification of maintenance and installations performed by HVAC contractors. The work included a performance-based renovation pilot program, which culminated in a field data collection effort that demonstrated significant energy savings for each system renovated.

Perhaps more importantly, it provided a strong correlation between measured performance improvement and savings at the meter.

Sharing Knowledge within the Industry

As our industry shares these concepts with broader audiences and collaborates with utilities, regulators, and state government, we can better quantify and improve installed HVAC system performance. As a result of the HVAC Industry’s involvement, NCI began the process of developing ASHRAE 221P, a Test Method to Field-Measure and Score the Performance of an Installed Unitary HVAC System.

We want to share a key piece of what we learned so the industry can offer a higher standard of quality. Currently the standard development process is well underway, with publication expected sometime in the first half of 2018. ASHRAE 221P details the procedures, calculations, and instrumentation required to measure system capacity and efficiency in the field.

If You Don’t Measure, You’re Just Guessing!

Over the past two decades NCI has trained and certified more than 25,000 HVAC Industry professionals in Performance-Based Contracting?. They have also provided professional services to one of the nation’s largest electric utilities. Because of those experiences, the greatest opportunity for reducing peak demand and energy use is to target the installed base of inefficient HVAC systems. This is done by addressing performance degradation and equipping installing contractors to sell and install Performance-Based HVAC systems. As a result, consumers will become more informed about their HVAC systems and better understand how performance affects their comfort and operating cost.

Consumers who know what they need to do will expect contractors to provide services that prevent performance degradation. These consumers value maintenance that sustains overall system capacity and efficiency.

[1]? The final CLTEESP was released on August 20, 2008. California’s Long Term Energy Efficiency Strategic Plan – September 2008 – Original version of the Strategic Plan adopted in D.08-09-040 and is available at:

?

Recent Comments