When a blower circulates air, it faces two expected obstacles on its journey through the duct system ‘ the coil and filter. The cooling coil is usually the airflow’s takeoff from the fan and the air filter is the landing near the end of its journey through the system. These two parts of the trip are expected to be bumpy. Ideally, during the rest of the trip, airflow should enjoy ‘great weather and smooth sailing.’

Let’s have a fresh overview and take a look at how you can forecast and eliminate high-pressure issues in HVAC systems using static pressure diagnostics. In the U.S., we use inches of water column (w.c.) as our pressure unit of measurement. This is the distance, measured in hundredths of an inch, that pressure will push or pull water in a U-shaped tube.

Effects of Pressure on Airflow

Resistance to airflow often negatively affects static pressure in a forced-air HVAC system.

Each fan has a maximum-rated total external static pressure (TESP). If it exceeds the maximum-rated pressure when measured, airflow decreases, system performance takes a nosedive, comfort suffers, and utility bills skyrocket.

Your job is to find and eliminate the causes of excessive airflow resistance to increase efficiency and comfort. Unfortunately, most systems suffer from measured TESPs that are more than 150% of maximum-rated pressure. This problem usually goes undetected.

Total External Static Pressure

static pressure.

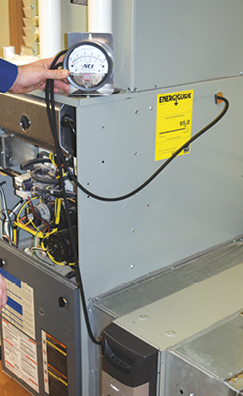

Total external static pressure is the first air pressure you’ll measure and calculate when you diagnose an HVAC system. As a fresh overview, it only takes a few minutes to measure pressure before and after the air-handling equipment. Then you simply add these two pressures together and compare it to the maximum-rated TESP.

If measured TESP is 20% higher than maximum-rated fan pressure, your job is to continue static pressure diagnostics to find and eliminate the cause(s).

NCI publishes various static pressure budgets for several system types. Find NCI static pressure budgets in your training manuals, NCI’s online training modules, or on the NCI website at ncilink.com/PSIBudgetTable.

The Cooling Coil

The highest airflow restriction in many systems is often the cooling coil. It is usually located at the fan discharge, at the beginning of the duct system. Many higher efficiency cooling coils have resistance to airflow greater than the fan can afford.

Our studies show coil resistance to airflow in well-performing systems does not exceed 40% of fan-rated pressure. So, a fan rated at .50′ w.c. should not exceed .20′ of static pressure (.50′ x 40% = .20?).

Pressure drop over a coil is found by installing test ports (ncilink.com/TestPortInstall) into the air stream before and after the coil. The pressures are taken and recorded, then subtracted from each other to find coil pressure drop. Compare measured coil pressure drop to 40% of fan-rated pressure.

Click Below for the next page:

Recent Comments