HVAC Contractors already made enormous investments in service management software, automated field service technologies, as well as facility, utility, and third-party programs.

Right now, current approaches with these technologies strand thousands of comfort systems that deliver less than 60% of what manufacturers promise in their capacity and efficiency ratings. What’s worse, these systems under-perform and under-deliver when they are needed the most.

As utilities adopt Time of Use Rates (TOU’s), customers see new pricing signals. This signal shifts energy use from peak hours to off-peak hours which penalizes end-users for excessive HVAC energy use. In addition, in the Western U.S., a bold movement toward ‘building electrification,’ will change reliance from gas to electricity in residential and commercial buildings.

What most regulators and utilities don’t realize is the margin of error with heat pumps is even less tolerant than gas equipment to these confounding variables.

Testing and Measuring Are Key

What I find most alarming is that we don’t expect technicians to measure and correct an HVAC system that is not performing to its designed capacity and efficiency ratings. No one in the value chain knows, expects, or requires this to happen.

If HVAC technicians don’t measure manufacturer equipment ratings in the field, who will?

Businesses are being built upon assumptions that exclude a customer valuing how well their entire HVAC system is performing. Unfortunately, by continuing to make these uninformed assumptions these issues will penalize your customers’ safety, comfort, and efficiency as well as your business’ value proposition!

This also means consumers don’t appreciate technicians for their contributions. The customer value proposition, contractor differentiation, and increased selling prices and profit margin, remain out of sight until the business owner decides to require measured field performance.

If what ASHRAE states is true, shouldn’t we be building workforce professionals who focus on HVAC system performance, who know their identity, and who have strong values, practice work ethics, and exhibit craftsman-like behavior?

Our industry is positioned to change the consumer view of HVAC from a commodity to a well-performing asset that increases the value of homes and buildings. Performance-based HVAC contractors are the only ones capable of doing this and here is why: professionalism.

Measurement is a Path to Professionalism

In the old days, a coat-of-arms distinguished ‘professions.’ Professional people took the time to study and train. This is how they established their individual identity. They then perceive themselves as professionals. They don’t need a brand, association, or company to identify their worth. Yet, they recognize their individual value and know why they are important.

A person without a coat-of-arms often associates their identity to things outside of themselves. They experience more uncertainty in terms of their value. They question their problem-solving skills and struggle with adaptability.

Click Below For Next Page

Just looking at the outside does not distinguish a coat-of-arms professional. Any novice can provide a 15-point clean and check, a summer/winter visual inspection, use an industry/association consensus checklist approach, or even conduct a refrigerant circuit analysis.

These approaches won’t distinguish a company, nor will they reveal what is plaguing system performance.

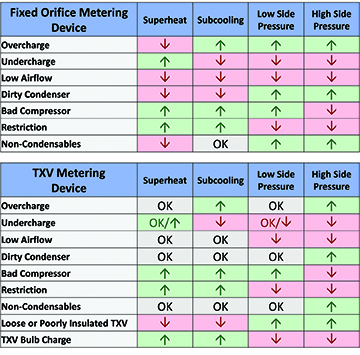

We must take measurements beyond the refrigerant to address electrical and mechanical issues. These range from supply/return air balance, control system problems, fan performance, compressor performance, to the delicate balance of refrigeration temperature and pressure, superheat, and subcooling.

The most overlooked is airflow, which is foundational to air conditioning performance. Yet, the published data for these performance factors differ between laboratory environments and real-world in-field applications.

Building Professionalism

This coat-of-arms comes from building and mentoring each technician’s professional identity in HVAC system performance. As an industry, it is our job to help them become comfortable with their professional values. We must understand their specific job requirements, and develop the skills needed to meet the demands of a changing workforce.

Professionals must know how to use the right instruments and tools. Their confidence comes from hands-on training. All of this positively impacts HVAC system performance.

We have found that, on average, trained and certified technicians can improve a system’s delivered capacity by more than 50%. Not only will consumers receive what manufacturers promise in their capacity and efficiency ratings, but now performance can be valued by customers.

This means we can now address the perception issue within the HVAC Industry head-on! People can know who they really are, what they really do for their customers, and why they really matter to their community. HVAC businesses can now differentiate themselves with professional people who believe in themselves and know they deliver all the potential of the brands they carry.

The bonus value is that they can increase the margins and volume of the products they sell and install while expanding their service agreements.

Now is the time for HVAC contractors to grow their customer bases. Contractors should increase the number of jobs they do, raise profit margins, and scale-up the performance of their staff.

At the same time, these professionals will reduce performance callbacks while increasing customer satisfaction. There has never been a more opportune moment to raise morale and create a performance-charged work environment.

Mel Johnson is vice president of utility programs at NCI. His background consists of nearly two decades of experience within the energy utility and HVAC Industry. He continues to interact with a broad array of stakeholders, associations, industry trade allies, and end-use customers. Mel has created, directed, supervised, and governed mass-market Investor-Owned Utility projects mandated by the State of California through the CEC and the CPUC.

Recent Comments