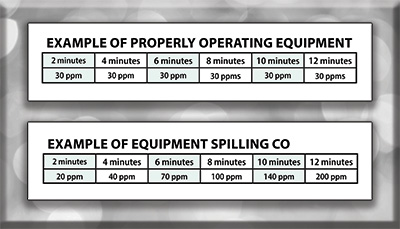

The only way to verify if spillage is happening is to take multiple CO measurements in the flue gas while the equipment operates. Stable CO readings below 100 parts-per-million (PPM) indicate the equipment is venting correctly. Rising CO readings during the run cycle indicate flue gas is spilling.

In the example at the top of the page, the CO measurement remains stable as the equipment continues to operate over 12 minutes. The CO readings stay below 100 PPM and are stable. In the above example, the equipment is venting properly.

In the second example on the top right of this page, the CO measurement continues to climb and doesn’t stabilize. This pattern shows an appliance spills flue gas and is unsafe to operate. CO levels will continue to climb until the equipment cycles off.

If you focus only on the equipment to solve CO spillage, you may be looking in the wrong location.

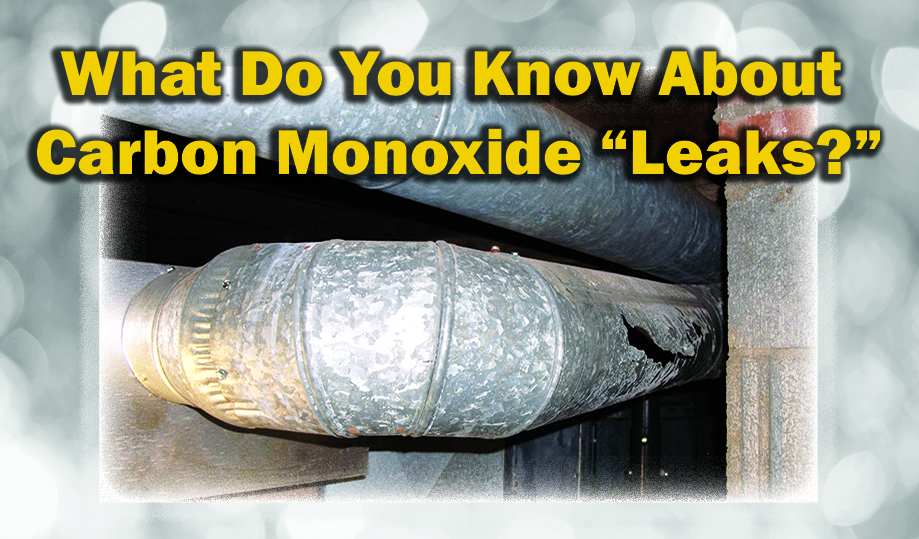

If it operates long enough, CO levels will rise so high that a combustion analyzer won’t be able to display the reading. A traditional test will miss this safety issue.

The Solution

You can only find the cause of spillage through proper testing, equipment monitoring, and using fewer assumptions. A properly designed and operating system shouldn’t spill CO. If it does, the built-in safeties should turn the equipment off so it doesn’t endanger anyone.

If you focus only on the equipment to solve CO spillage, you may be looking in the wrong location.

Many causes of CO spillage have nothing to do with the equipment. Instead, they have everything to do with the equipment’s environment.

External influences such as exhaust fans, duct leakage, airflow imbalances, and building pressures often interfere with proper draft and cause spillage through an interaction known as back-drafting. A firm understanding of building science and diagnostics is priceless when diagnosing back-drafting issues.

Here’s an idea: offer low-level CO monitors to your customers instead of over-the-counter CO alarms. Many believe store-bought CO alarms provide the same protection as low-level CO monitors. They don’t.

Your customers deserve a device that prevents exposure to excessive CO levels before they alarm. Why not equip them with a safeguard that lets them know they are at risk before harmful levels build up?

Unfortunately, some contractors will continue to use CO leaks as an excuse for their lack of understanding and troubleshooting skills.

Don’t be that person. Instead, move past the excuses and find out the actual reasons. We can improve our industry and our customers’ safety with proven solutions that prevent CO poisonings from ever being a news story again.

Recent Comments