In the 1820s and 30s, Englishman Charles Babbage invented the forerunner to the modern computer. He called it The Difference Engine – a mechanical system for doing complex calculations that, had it been completed, could have put the British Empire permanently ahead of all its national competitors in science, technology, military, and power.

Unfortunately, the Difference Engine was so far ahead of its time that very few supported it. As a result, it was only partially built, never implemented, and left the doors wide open for Britain’s competitors to move in and take power.

There are many difference engines in the HVAC universe today. One of them is the high-performance approach to HVAC contracting, which calls for including ventilation as part of the overall system.

As such, this science-based method is very different from how most of the HVAC Industry approaches business. Most contractors today focus only on the equipment. But comfort, energy efficiency, and safety involve much more than that.

This difference engine opens the door to many opportunities for contractors. It can set them apart from everyone else in their marketplace.

What High-Performance Contractors Are Saying

Last month High-Performance HVAC Today magazine surveyed its 15,000 readers. We wanted to find out how this service and installation delivery method impacts their business. Here are some things they told us. First, of the respondents, 86% are HVAC contractors. Furthermore, 70% spend time and money training their installation and service technicians how to test, measure, and diagnose system issues.

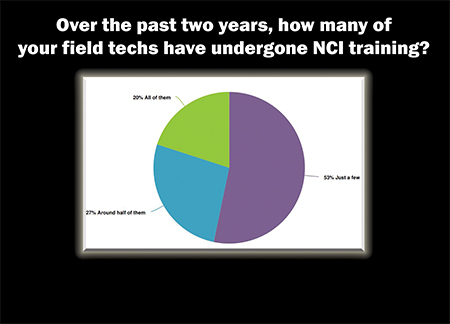

In fact, over the past two years, 47% of the respondents say they have sent from half to all of their field technicians to High-Performance HVAC training taught by National Comfort Institute (NCI). Based on that training, many have implemented testing and measuring into everything they do. This implementation means performing static pressure measurements and tests (63% of them). It also means they do temperature measurements and tests (53.3%) on every call.

From a safety standpoint, 43.3 % of the respondents say they also conduct carbon monoxide testing on every call.

They capture the results of their testing measuring in various ways, with 76.6% of them using paper forms. But the digital age is upon us. A growing number of contractors are using mobile apps to record the data. They also use it to help educate customers so they can make the right buying decisions.

Among the app tools they use:

- 13.3% use NCI’s AirMaxx™ or AirMaxx Lite™ mobile app

- 36.7% use other digital means.

Among the apps most often mentioned by respondents are Fieldpiece Job Link® and iManifold®. Respondents also say they use spreadsheets, in-house proprietary software, Aptora® Mobile and Measure Quick apps, and others.

Click Below for the Next Page:

![High Performance Contracting: Summit 2018 Panel Discussion on Implementation [PART 2]](https://hvactoday.com/wp-content/uploads/2018/06/DSC_0613-Panel-Discussion-4c3-440x264.jpg)

Recent Comments