Dawn Vickers-Mroczek

Communication and organization are important to any company’s success. Without these qualities, jobs often don’t work out well and can end up going wrong due to making assumptions.

Duct renovations can have a lot of complications if you don’t communicate the scope of work up front and organize the materials. Multiple supply house runs and needless duct repairs often occur when we don’t communicate the right way.

Advanced duct renovations often require more than pictures and quick descriptions. They require coordination and being onsite to show and explain needed repairs.

This shows your installation team and customer that we appreciate them and opens the door to addressing any questions or concerns upfront. Everyone is on the same page.

Mistakes Happen

For example, we had one duct renovation where crucial duct repairs were missed, and we made assumptions that led us to not delivering what was promised. That put us in a tough spot since the customer expected the solution we sold them, not what we delivered.

Mistakes happen ‘ how we address them is a choice each of us must make. In this situation, we made repairs the best we could to get close to the results we promised. This was costly in time and material. We knew something had to change so this wouldn’t happen again.

In other words, we had to confront some brutal facts. By doing so, this experience proved to be a game changer for our company.

Communication

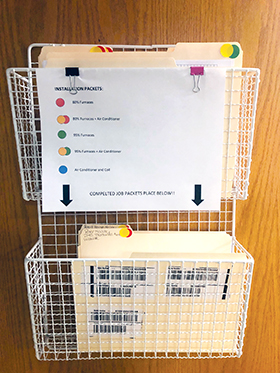

The first action we took was to prepare job packets consistently. We’ve had job packets for years, but they didn’t always contain what installers needed. We had to define what would go into each packet and keep it in a consistent format so that everyone knew what to expect.

The job packet is like a football playbook that keeps all the players on the same page. The salesperson is the quarterback and must make decisions so the team can make the right play to get to a first down.

A properly designed and prepared job packet leaves no room for misunderstanding. Here is a list of items we now include in all our job packets:

-

To improve communication, GV’s went to a consistent format for their job packets to assure installation teams have all the right information in one location.

Equipment information

- Copy of the customer proposal

- Detailed list of completed repairs

- Digital photos of problem areas

- Copy of Air Distribution Worksheet

- Floor plan

- Duct schematic

- Field drawings

- Combustion Analysis Reports

- System Commissioning Report

- Air Upgrade Report

- Copy of Manual J – Short Form.

Next, each job requires a pre-meeting. The day before the job, we gather the team together and go over the project. Think of this like the quarterback huddling with his receivers. They leave the huddle knowing what route to run and who is fulfilling each role. There is no confusion about who is doing what.

The final communication protocol we established was reviewing the job to ensure it is going as planned. This review happens at the end of each day. We go over that day’s work and if issues come up we decide, as a group, how to correct things, instead of letting them go or making assumptions.

To assure our systems perform as sold, the installation teams verify their work. If they miss something, they can take care of it before the customer knows.

Our installers are totally stoked to see the awesome job they do. This completely changes everything. They now own the results.

Organization

To address our brutal facts, one of our first actions was to provide installers with consistent supplies. We put together furnace bins so the proper materials for each furnace installation are already pulled and accounted for. In addition to these bins, we also built copper, PVC, electrical, and gas fitting bins, so every installation team has what they need. This keeps them from running to the supply house to chase down missing items.

Outside one of GV Heating’s standardized installation bins.

Next, we added parking lanes to our warehouse floor. These help us physically organize materials. We use a whiteboard to list job essentials that must be pulled before it can go out. The parking lanes have all the components pulled and waiting so each team can go straight to their lane and get what they need for the job.

This reduced our wasted shop time by 30 minutes per team per job. Our supply house delivers the materials and places them in the appropriate lane based on the job number. I don’t have to do any extra work, all I do is communicate the proper job and materials to our distributor.

The last action we took was to prepare duct renovation kits. The kits address the most frequent return and supply repairs we make in our market. They are:

-

Stock contained inside the standardized installation bin.

8? Basement Return Kit

- 10? Basement Return Kit

- Supply Plenum Kit

- Return Air Drop Elbow Kit.

With these kits, we have all the materials pulled and ready to go if the salesperson notes that renovation is needed.

The Results: Success and Profit

Equipment is organized each morning in new ‘parking lanes.’ This reduces 30 minutes of wasted time per crew per job.

Since we addressed the brutal facts behind our duct renovation issues, our test-out numbers have improved. While it was uncomfortable at the time, we’ve grown from the experience. We had a choice to ignore the problem or confront it.

I’m happy to say we took it on and made our duct renovations more successful and profitable. As a result of these changes, we are now finishing jobs on time or early, with our installers never needing to make runs to distributors for supplies.

Our installers are now spiffed for their performance as we measure and verify. They are compensated just like our service technicians and rewarded for awesome results. Last year we had 156 hours of supply house time before we made these changes.

Once we improved our communication and organization, these numbers dropped by 80%. This has helped us achieve our goal of increased duct renovation success and profit.

Small changes and adjustments in our operations yielded big results that we never would have known about unless we had that original problem.

Remember, mistakes happen ‘ how we address them is a choice each of us must make.

.

Meet Dawn Mroczek at NCI Summit 2019

Dawn Vickers-Mroczek

High-Performance HVAC Summit 2019 is happening April 15-18 in Orlando, FL. Dawn Vickers-Mroczek is one of five Performance-Based Contractors’ presenting how they bring High-Performance into their companies and their marketplace. She is a comfort consultant for GV’s Heating and Cooling, Inc. in Glenview, IL.

Dawn will share how to create a well-oiled process for handing sold jobs off to installers. This process not only improves installation quality but can make it more profitable as well.

Come meet Dawn and network with your peers in Orlando. Learn more about the Summit 2019 program at GoToSummit.com.

After Summit, stick around for our Post Show Training classes. Go to ncilink.com/PostShow for details.

Register today. Questions? No problem. Call 800-633-1850 and talk to your customer care representative.

Recent Comments