If you’re like me, your journey with inverter-driven systems started with a mix of curiosity, confusion, and maybe a little frustration. These systems are powerful, efficient, and sometimes downright unpredictable.

They promise all the efficiency in the world, incredible comfort, and ultra-quiet operation. But they can also leave techs scratching their heads, wasting time, and burning refrigerant (and money) if we don’t handle them right.

Over the years — through testing, missteps, and lots of conversations with technicians and trainers across the country — I’ve picked up a few things that might save you some grief.

So here are 10 key lessons about inverters I’ve learned as a contractor, trainer, and fellow tech. These aren’t abstract theories—this is real-world stuff you can use tomorrow.

Inverter Doesn’t Mean Only One Thing

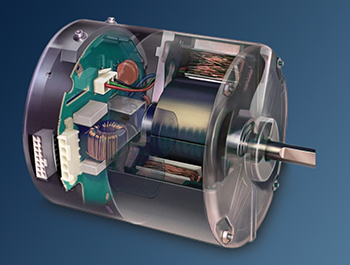

People often ask me to explain “how inverters work.” But there’s no one-size-fits-all answer because “inverter-driven” equipment comes in all shapes and flavors. There are true variable frequency driven drives like what you find in commercial applications where you’re using normal three-phase motor-driven VFDs. On the other hand, you have brushless DC versions that use permanent magnet motors. These are different, they behave differently, and require different troubleshooting approaches.

By the way, an ECM blower is technically an inverter-driven motor. So is a ductless mini-split. But the way they operate, respond, and fail can be completely different.

What matters is understanding that inverters control motor speed by converting AC power to DC and then back again to mimic variable-frequency AC. That’s the gist. But manufacturers rarely tell us exactly how they implement their control strategies, so don’t expect to know everything going in.

Compression Ratio Still Matters

When it comes to inverter performance, compression ratio (head pressure divided by suction pressure) is a big deal. Airflow, in both cooling and heating modes, is a big part of heat pump compression ratios. For example, in heat mode, if the outdoor unit has bushes around it, that can drive down evaporator temperature, which will drive up the compression ratio.

If the heat pump condenser is inside the home and there isn’t enough airflow in heat mode, that can also result in higher compression ratios.

A high ratio equals inefficiency. But here’s the rub: sometimes we need high compression ratios.

Click Below for the Next Page:

Great Article! I will use it to reinforce to our techs that what we do over here is what you do as well to make sure inverter systems and single/2-stage systems work as they should and to ensure customer satisfaction is exceeded.