Last month, authors Ben Lipscomb, P.E., and Dennis Mondul began discussing the importance of humidity for indoor comfort, air quality, and health. They covered humidity problems that impact these factors as well as building integrity, how to manage cooling humidity, and more. You can read Part one here: ncilink.com/HumidIssues2.

In part two, they get into more detail on the technology side. They then show how you can help customers stay comfortable, healthy, and happy.

How Can You Help A Customer Manage Humidity?

Offer them a two-stage system with a multi-speed blower as an option. Many of these systems run at around 60% of capacity for a portion of the on-cycle. So they tend to run longer and more dehumidification takes place.

While two-stage systems can help to some degree, that often won’t be enough to truly maintain optimal humidity levels. That said, an improvement is an improvement. If that’s what the customer can afford, then it’s your job to make it happen.

The more exciting option for customers like Suzy may be the fully modulating variable capacity or “inverter” system.

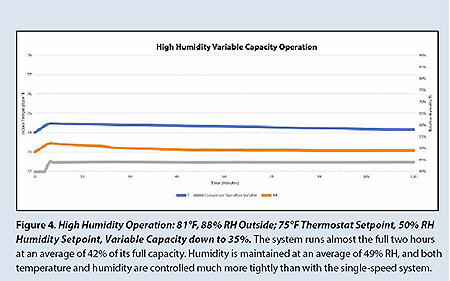

These systems can reduce capacity even further, resulting in very low cost, longer runtimes, and much better dehumidification over a wide range of conditions.

They can also help maintain a humidity setpoint that allow the system to run for dehumidification, as long as the temperature is above the lower limit set-up at the thermostat.

Let’s address the humidity problems this way. By design, an inverter system adjusts capacity base on the load.

Therefore, when outside conditions require the removal of 18,000 Btus per hour, a three-ton system adjusts the compressor and blower to operate more like a 1.5-ton system.

This allows the removal of heat and removes the proper amount of moisture due to the longer run time.

In fact, Suzy can now set the system to provide a stable 50% RH along with a 75°F temperature set point.

Once Frank and Suzy understand why she is uncomfortable in her home and understand that an option is available that resolves the issue, they may insist that you install a variable capacity system.

This occurs far more often than experienced contractors might suspect.

Low Humidity in Heating Season

The obvious solution for adding humidity in the winter is to add humidifiers. Many folks do this by buying a cheap standalone humidifier.

In Northern Montana, Ben doesn’t need central air in his home, so he has gone with standalone humidifiers. At first, he and his wife bought a single humidifier from a box store for around $30.

It turns out that these humidifiers are only designed for a single small room, such as a bedroom. These devices also run out of water requiring refills at least once or twice every day.

After dealing with humidity problems caused by dry air in every room for years, he bought another similar unit for his bedroom. Ben also bought a larger one for the main living area. With these three humidifiers, he can keep the indoor humidity between 35% and 45% RH all winter. But they must remember to fill them at least once a day.

Furthermore, standalone humidifiers also require regular cleaning to prevent the build-up of hard water deposits and bacteria. To be honest, it’s quite a hassle to regularly fill and clean three humidifiers!

Click Below for the Next Page:

In SW Florida we have run into a lot of sweating ductwork with these new Variable speed systems unless the ductwork is upgraded to R-8. the runtimes are long enough to make R-6 insulation insufficient. The manufacturers do not mention this in their literature but they want to sell more equipment of course. Just an observation from SW Florida.

Charles, that’s great feedback! Thanks for sharing your real world experience with these systems. Good duct systems are definitely the first step in dealing with many comfort issues, and equipment upgrades should always be viewed as the cherry on top.

This article is very lacking in a true understanding of staged and inverter equipment. The turndown is based on a sensible reading from the thermostat. And while the sensible load may be reduced and the equipment turns down to match the load more often than not the latent load stays the same.

Due to the load diversity of all equipment including stage and inverter (roughly 70% sensible 30% latent) the equipment turns the latent capability down to all most nothing. And the latent load is still a full latent load even at none peak conditions.

So even if you get longer run times it is nowhere near enough to overcome the equipment diversity and dehumidify properly. This makes staged and inverter equipment very emery efficient but actually terrible at dehumidification.

Hello Jeremy.

I am posting Ben Lipscomb’s response to your question:

====================

Thank you for your comment. The key to an inverter system managing humidity lies not only in inverter compressors to extend runtimes, but also in the variable speed blowers that they typically come with.

Using a humidistat, it’s possible to put most of these systems into a dehumidification mode that slows the blower speed dramatically. This shifts more of the capacity to latent cooling and helps the system achieve a better balance between temperature and humidity control.

It’s still not a foolproof system, as eventually the thermostat will be satisfied and shut the system off while the humidity could remain higher than desired. Allowing the system to overcool a bit below the setpoint is an option here, but in very humid areas a better solution would be reheat to allow the system to dehumidify all the way down to the humidistat setpoint while maintaining comfortable temperatures.

The devil is always in the details, but the flexibility afforded by inverter compressors and variable speed blowers has the potential to help a lot with humidity problems when properly executed.

Ben Lipscomb, P.E., Director of Engineering

National Comfort Institute Utility Services

I don’t believe sweating ducts are caused by longer runtimes – my experience is that the problem arises from reduced supply air temperature.

As mentioned by others, variable-speed air handlers controlled by thermostats with active dehumidification capability can and do reduce cfm per ton to wring more water out of indoor air. That reduces supply air temperature and con then overwhelms the ductwork insulation’s ability to prevent condensation/sweating.