Moving Forward Toward Success

Once you begin down the performance path, it becomes a matter of doing what it takes to keep heading in the right direction. Which is what lead to this question.

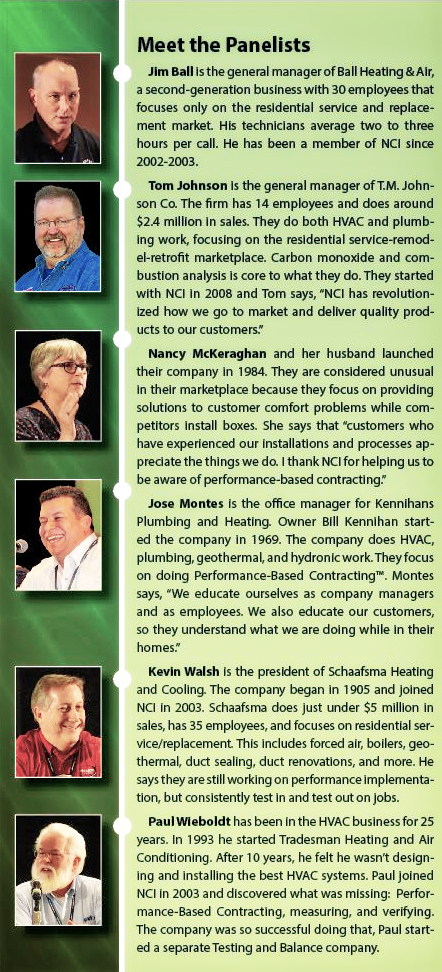

Q: Dominick Guarino: Please share with us how have you moved forward in your implementation process since the last Summit you attended?

A: Ball: We always do static pressure testing after every changeout. We have now taken that a step further by doing the reports. Not a big step, but it is helping.

Jose Montes: One of our biggest issues is with staffing. Last year we hired several new people. Performance training has been continuous for our new crew and all our other co-workers.

It’s unfortunate, but when we hire new people, we need to start from ground zero in training them. It doesn’t matter if they have HVAC experience or not ‘ they just don’t know anything about performance.

They also know next to nothing about combustion or airflow, so we train them in those disciplines as well.

The good news is that our core technicians DO understand it, so they share what they know with the new hires. That means it’s not just management pushing performance. The employees are a great help as well.

McKeraghan: One of the things I’ve learned in the past year is that we have two types of customers: internal and external ones. We tend to take excellent care of our external customers. After all, they pay our bills.

But we often forget about internal customers — our employees. We tend not to think of them as customers. But they are. They are part of the process. So we needed a cheerleader.

When I attend training or events like Summit, I bring my sales manager — Will Horner — along with me. That way, he knows what I know, and he gets all fired up. When we get back to the office and find our performance culture wandering off the trail a bit, he reminds me, and we get back on the trail. And I reciprocate that with him.

Processes and Success

Processes and Success

Performance-Based Contracting involves using processes ‘ technical ones in the field, management ones in the office. This section revolves around how to get technicians and installers active in doing static pressure testing before and after working on a job as well as some details on very specific service/maintenance processes.

Q: Ed Barrett, Barrett Heating and Cooling, Alton, IL: I am curious how you get your techs to take their time and do the static pressure and other measurements during the height of winter or summer busy seasons?

A: Montes: We look at our invoices daily. There better be some airflow and combustion numbers in there. Otherwise, we have a conversation. Daily. Until they understand.

This isn’t negotiable. It doesn’t matter what time of the year it is. It has to be part of the invoice.

McKeraghan: Our technicians get $5 more for every job they do that includes a diagnostic or maintenance. When the tech looks at how much more money they make when they do these things, they can see I’m serious.

Tom Johnson: It needs to be a big cultural thing in your company ‘ from the call-taker all the way down. At our company, the technicians are assigned one call at a time. When they finish that one, they get the next one. They don’t know how many calls they have that day or any day.We try not to give them too many calls each day because we don’t want to run them ragged. This is a long-term culture shift. It means building a good, strong maintenance base, and doing maintenance right so you don’t have summer or winter breakdowns from that base. Bottom line ‘ you can’t take every call.

Q: Dominick: What Tom is saying is you have to prioritize. Static pressure measurements should be part of your standard maintenance call. It is a priority thing. It is a maintenance thing. And it is not optional.

Another obstacle to implementing is getting your salespeople on board. I typically hear contractors from all around the country say things like, ‘My salepeople are doing well, they are selling more than $1 million a year, so why should they change??

So, what have you found that works to help get over that hurdle with the salesperson?

A: McKeraghan: We’ve struggled with this for a long time. One thing that really helps is Rob Falke’s chart that compares static pressure to blood pressure. For the first time, we have something we can take to customers and share the information we collect from their equipment in terms they can understand.

Once salespeople had that tool, it became much easier to not only get them on board, but it helped get the customers on board as well. Up to that point, we were the only company talking about performance, statics, and air upgrades. Nobody knew what we were talking about.

Another thing that solidifies salespeople doing performance testing is that we get our customers involved in the sales process. Customers will hold the Magnahelics and read the numbers off and become integral to the overall sales process.

Our sales manager did this first. When he became successful at it, the other salespeople wanted to do the same thing.

In other words, you need a crusader ‘ someone who will take it and run. You also need to provide your salespeople with backup, with the tools they need to take them through the entire process.

Also, NCI has this wonderful batch of consumer pamphlets, one of which describes the six-step process which we use all the time and find very useful. The others define static pressure and describe what air balancing is and so on.

That’s called third-party verification. It’s not us saying it. It’s a nationally recognized third party.

These are some of the things that help us be successful getting our salespeople onboard and educating our customers.

Got to next page

Recent Comments