However, it makes sense to find and build relationships with insulation and air sealing contractors in your area who know how to make the improvements and repairs that your customers may be need.

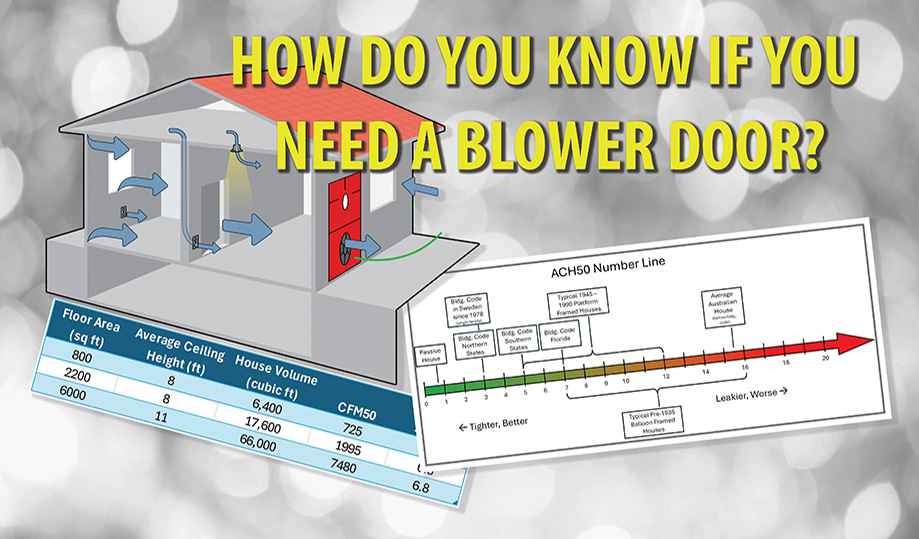

One easy way to screen an insulation contractor is to ask them if they own a blower door and how often they use it.

Take Aways

It’s certainly not necessary for every HVAC contractor to have a blower door system on their truck, but it probably makes sense for mid-sized and larger companies to have one technician who focuses on building science and has the necessary test equipment to help diagnose and solve problems in the building envelope and duct work.

For smaller companies, there is probably someone in your area that has equipment and expertise to do blower door tests and infrared camera scanning.

That person might work for an energy rater company or be part of a community weatherization program and be willing to work with you to help you solve the problems you face.

Thinking back to Chris Hughes and his uncomfortable conversation about expectations, we should all recognize the limits of new equipment. Expecting perfection from new equipment in an existing house with existing duct work is a little like putting the engine from a new C8 Corvette into an old, well-worn, 1998 Ford Expedition with its original air intake and exhaust.

If you did that you would never expect the vehicle to perform like the Corvette does on a racetrack. The Corvette engine might fit in the Expedition’s engine bay, but there’s a lot more to track performance than that! Everything must work as a system.

Steve Rogers owns The Energy Conservatory (TEC), a manufacturing company specializing in home performance. The firm produces the MINNEAPOLIS brand precision diagnostic blower door equipment and develops processes to solve building comfort, energy use, durability, and air quality problems. You can reach Steve at ncilink.com/ContactMe.

Across the U.S., many new houses will have a HERS rating. In Massachusetts, all new or substantially renovated houses will need to be HERS rated. This means builders and contractors will need a projected HERS rating to apply for a building permit. The projected rating is based on the plans, including an assumed leakage rate to which the house should be constructed.

The HVAC contractor can reach out to the HERS rater to get the specs that went into the rating to do a Manual J load calculation. Raters and heating contractors should coordinate. Also for sizing of the ERV.