Combustion/CO Safety Considerations

It is important to have a basic understanding of carbon monoxide (CO) safety and building science when making changes to the Combustion Appliance Zone (CAZ).

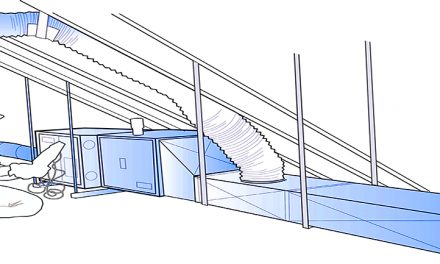

A basement can be substantially cooler than the rest of a home. A large return in a cold basement impacts the efficiency of an air conditioning system. Think of it like a bypass duct in a zoned system, adding cold air to the return will, at times, make the equipment operate outside of the manufacturer’s specifications.

Changing the pressure of a basement can increase the home’s infiltration and exacerbate the temperature difference between each floor of the house.

An example of this would be increased negative pressure in the basement during the heating season. When this occurs, cold air is drawn into the home through the lowest point. Increased infiltration also comes with an increase in airborne debris being introduced from the outdoors.

Radon is another hurdle that must be considered when installing a return in a basement. Radon is a radioactive gas that exists naturally in the soil and can enter the home through gaps and cracks in the foundation.

Changing the pressure in a basement can increase the amount of radon that enters a home. Adding a return can spread the Radon throughout the home, making a bad situation worse.

While most newer homes have clean basements, it is not uncommon for older basements to be damp and musty. A return can spread the basement smell throughout the rest of the home.

Delivered Airflow and Mixing

Increasing fan airflow has a direct impact on delivered airflow. If you increase one, then you increase the other. Increasing the delivered airflow improves air mixing within a home, while reducing areas of stagnant air.

This mixing improves overall comfort by promoting even air temperature throughout the living space.

By adequately mixing the air, there is a better chance that any airborne particles stay suspended until they reach the air filter.

Dust Free Sixteen filter (MERV 16) installed.

Pay attention to your selection of grilles, registers, and diffusers (GRDs) when you attempt to improve air mixing. High-performance GRDs can improve the outcome.

Air Upgrades Are More Than Comfort

An Air Upgrade is more than a duct repair package: it’s a system approach to airflow, filtration, and distribution that directly impacts your customer’s safety, health, comfort, and efficiency.

For example:

- Increased airflow improves particulate capture by improved mixing

- Better filtration captures more particles and helps improve fan airflow

- Relative humidity is important and can be impacted by changes to the system

- Duct leakage can have a dynamic effect on the IAQ and IAE

- Balanced room pressures can reduce infiltration/exfiltration and improve comfort.

When these elements are addressed together, Air Upgrades deliver not just efficiency but healthier, more comfortable homes.

As HVAC professionals, it’s our job to measure, design, and install upgrades that balance airflow with safety, health, comfort, and system efficiency. We’re not just moving air, we’re changing the environment people live in and breathe in every day.

Adam Mufich is an HVAC contractor who is now working as a curriculum developer and instructor for National Comfort Institute (NCI). If you’re an HVAC contractor or technician interested in learning more about Air Upgrades and IAQ, contact Adam at ncilink.com/ContactMe. NCI’s website www.nationalcomfortinstitute.com is full of free information to help you improve your professionalism and strengthen your company.

That’s absolutely true, and it’s one of the biggest reasons residential HVAC is such a mess. Manual J (load calculation), D (duct design), and S (equipment selection) are the foundation for correct sizing and comfort. But most homeowners never even hear those words, let alone see a report.

The problem is cultural and economic, not technical. Contractors have been trained—by market pressure to quote fast, not accurately. They rely on “rule of thumb” sizing: one ton per 400–500 sq ft, or “whatever was there before.” That’s cheaper in the short term but it locks in decades of uneven airflow, short cycling, humidity problems, and higher bills.

It’s ironic because the Manual J process doesn’t just size equipment; it exposes the building’s real load, often showing that the house air conditioning system can be downsized a ton or two with basic sealing and insulation improvements. In other words, a proper load calc is both diagnostic and preventative medicine, but it’s rarely prescribed.

The average residential HVAC contractor treats “engineering” as optional — until comfort complaints make it expensive.

The interesting question for the trade is how to re-frame that analysis as a value add, not a cost line. You can’t sell math to a homeowner, but you can sell quieter rooms, balanced airflow, and smaller bills. That’s where the Manual J conversation belongs.

At a minimum customers won’t buy what you don’t offer them.

HVAC needs to match the heat loss of the home in order to have good air flow; I wonder why this never gets mentioned.

We all know why; follow the money.