Part of your sales process is to show how this approach can help customers reduce utility costs and provide more value for their dollar.

That value is in the form of longer-lasting equipment and fewer equipment breakdowns.

In my experience, high-performance sales benefits employees by helping you create better career paths, generate better income, and provide job stability for them.

Selling duct renovations and air upgrades is year-round work and can contribute to personal growth and value.

Customer Education Should be the Focus

I view high-performance system renovation work not as something I sell but as something the customer invests in. We can teach customers about their homes using our training and the tools and instruments to test and measure.

Airflow testing and diagnostics is the right thing to do. Talking to customers is also part of any high-performance sales process. That is how we discover their pain points. Once we know their pain, we can help customers buy the best solutions for what THEY want and need.

By the way, educating customers is all about communication. It’s also about getting them involved in the testing process. Engaging with customers on this level, showing them proof of what is causing their HVAC systems not to perform as intended, nearly closes all our sales.

GV’s Sales Leads: How Do We Get Them?

At our company, we see three types of sales leads:

- Traditional Replacement Lead

- Service-Generated Call Turnovers

- Homeowners Seeking Solutions.

Traditional replacement leads come from our marketing programs. We focus on how our high-performance approach differentiates us from other contractors in our marketplace.

While on calls, we document what we do; in marketing, we document what customers tell us when we ask how we did.

And perhaps most importantly, we measure our marketing results. As NCI’s motto states, “If You Don’t Measure, You’re Just Guessing™.”

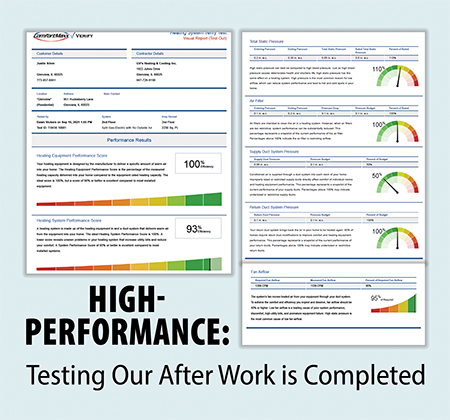

When we follow up on a traditional replacement lead, we are not looking at the equipment but also the overall heating/cooling duct system. We perform a full Performance Test on the system; static pressure, temperatures at the equipment, measurements of duct system, blower speed, fittings, etc.

Then we proceed to evaluate the duct system; supply registers, return grilles, temperatures at the supply registers and return grilles, sizing of the ductwork, counting the supplies/returns in the home, and performing a full room-by-room Manual J to verify the sizing of the heating/cooling equipment.

We inform the client that this process takes about 2-3 hours depending on the extent of the diagnosis. The performance of the existing system ranges from 55%-65% based on the data we collect and input into ComfortMaxx™.

Click Below for the Next Page:

Recent Comments