Jim Davis, Senior Instructor, National Comfort Institute

When it comes to combustion air, safety truths created by someone’s imagination — based on little or no factual data whatsoever — nothing but fairy tales. This article not only addresses the need to provide combustion air, but also highlights the realization that it might be a great idea to control it.

So what about providing combustion air? For example, assume your house is located next to a grocery store? Does that mean the house is automatically provided with food?

What if we knock two holes in the wall so you can see the grocery store? Now we have definitely provided the house with food, correct? ‘Well the fairy tale book states that if you make two holes in the wall, the food will come in (Said with tongue firmly in cheek).

Grimm’s Fairy Tales — the story of Rapunzel

But here’s a question: is it the house that needs the food or is it the people? Here’s another one — just how much food do they need? Sound ridiculous? So how are the combustion air rules we follow any different?

We Base Combustion Air Rules on –

Do we know how much combustion air to provide based on the principles of combustion and equipment design? Or do we just follow the Mechanical Code? Code states that we must provide 50 cu.ft. of air per 1,000 Btuh of input, regardless of the equipment type. This standard predates the current design of all induced-draft equipment and doesn’t truly apply to equipment with barometrics versus draft hoods.

Based on actual combustion requirements, a 1000 Btuh furnace needs 10.5 cu.ft. of air to burn at perfect combustion. Because that is not possible, we need an additional 4.5 cu.ft. of air. Therefore 15 cu.ft. of air handles the normal combustion process.

Now think about the dilution air for draft hoods and barometrics. A draft hood, based on design, uses approximately the same amount of air as the combustion process or an additional 15 cu.ft. So equipment with a draft hood would require a total of 30 cu.ft. of air per 1,000 Btuh.

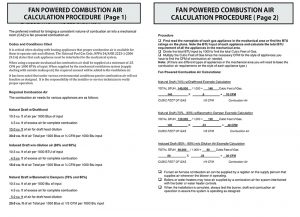

FIGURE 1: NCI’s Combustion Air Charts

Take a look at the NCI combustion air charts (See Figures 1 above): the combustion air needs of induced draft or condensing equipment would only be 15 cu.ft per 1,000 Btuh because there is no dilution air. Barometrics do introduce some dilution air into the flue so the requirements are slightly higher (20 cu.ft. of combustion air per 1,000 Btuh). In all cases Code still requires 50 Cu.ft. of combustion air per 1,000 Btuh for all types of equipment.

Beauty and the Beast Art by David Renn, Deviant Art (postapocalypsia)

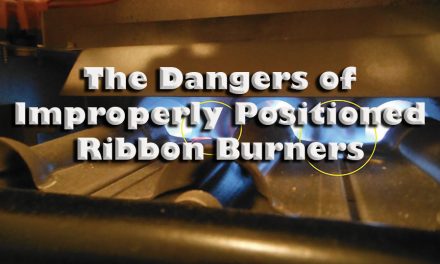

Regardless of required or needed combustion air volume, will a couple of holes in the wall or ceiling or a louvered door guarantee we provide it? To move air from one location to another requires negative pressure. This means our mechanical room usually must be in a negative pressure situation. Unfortunately this is exactly the opposite pressure necessary for proper venting. Flue (exhaust) pipes are also holes communicating with outside air. If the mechanical room is at negative pressure, what keeps air from pulling in from the flue? This is like gambling on Red or Black, Odd or Even on a roulette wheel. But let’s imagine it does seem to work as it does in many cases. Does bringing air into the room determine if it is actually going to the HVAC equipment? Don’t we need to control this air and deliver it to that equipment?

What Controls Combustion Air?

The answer is the draft! Whether natural or induced draft equipment, draft draws air into the burner. This draft, which is in negative pressure, must be greater than any other negative pressure that communicates with the equipment. Because draft is created in the equipment flue, the only way to draw air into the burners is if the flue is connected, not just nearby. This is an ongoing problem for equipment with a drafthood designed to separate the equipment from the flue.

The next problem with controlling combustion air to the burners is that draft constantly changes. This means combustion air constantly changes. Somehow we can always regulate fuel, but no one seems to think it important to regulate combustion air.

Just providing passive openings does not assure proper combustion air will be available, especially when it depends on the mechanical room being in a negative pressure. This is why NCI recommends only mechanical combustion air (fan-forced) be used to create a neutral or slightly positive pressure. Using mechanical combustion air assures proper air to the mechanical room under most field conditions, except extreme negative building pressures. ‘Again, it is draft that controls whether or not air gets to the burners. For draft to be effective, the flue must be attached to the equipment. This makes draft hood equipment somewhat useless.

The way the HVAC industry calculates combustion requirements is more of a guess than a calculation. The way the Code requires combustion air to be supplied is haphazard and counterproductive. The fact there are no Codes or protocols to verify or control combustion air to the burners outside the NCI teachings, lands us in the world of make believe.

Recent Comments